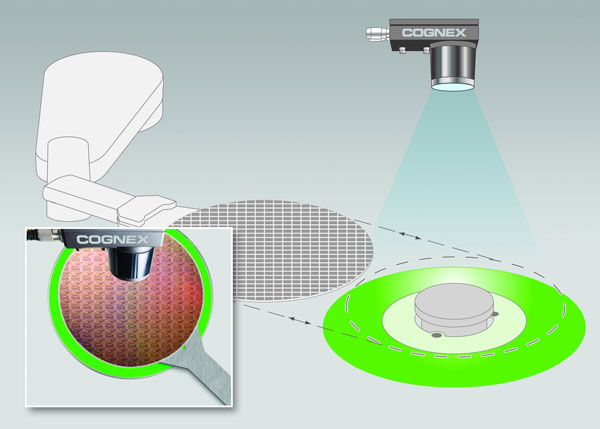

Natick, MA, – Cognex Corporation (NASDAQ – CGNX), today announced at SEMICON Japan the In-Sight® 1820 vision-based wafer pre-aligner. Utilizing proprietary Cognex NotchMaxTM alignment technology, the 1820 vision system provides precise non-contact measurement of wafer position and orientation that is faster and more accurate than comparably priced mechanical systems.

The In-Sight 1820 determines wafer position and orientation in less than half a second while mechanical pre-aligners must typically spin wafers for several seconds. NotchMax, the newest member of Cognex industry-leading PatMax® family of geometric pattern finding technologies, aligns wafers with a center position accuracy of ± 15µm and an orientation accuracy of +/- 0.05 degrees. More accurate pre-alignment saves fine alignment steps inside a process tool to boost throughput.

“Cognex is the world leader in semiconductor high-precision wafer alignment, and the In-Sight 1820 leverages that experience to bring world-class Cognex vision technology to the wafer pre-alignment process,” said Marilyn Matz, Cognex Senior VP, Vision Software. “In addition to throughput and accuracy gains, capital equipment manufacturers will appreciate the system’s ability to handle changing wafer sizes and types with simple parameter changes, while semiconductor fabs will like the non-contact design that minimizes wafer handling and potential damage to the wafer.”

The In-Sight 1820 is available now.

.: Design World :.

Filed Under: Data acquisition + DAQ modules, Semiconductor manufacture, Motion control • motor controls, Mechatronics, ELECTRONICS • ELECTRICAL, Vision • machine vision • cameras + lenses • frame grabbers • optical filters

Tell Us What You Think!