Southborough, MA — Novotechnik introduces the RFA4000 angle sensor, which determines the measurement angle by detecting the orientation of a magnetic field using a magnet, which is easily attached to a rotating shaft on the application.

The magnetic field orientation is converted by an embedded IC into an angle from the 0 to 360º. An integrated processor performs several functions including converting a calculated angle to either a 0.25 to 4.75V or 0.5 to 4.5V radiometric output. Because the RFA4000 is based on touchless technology there is no physical connection between the sensor and magnetic position marker, making it inherently wear free.

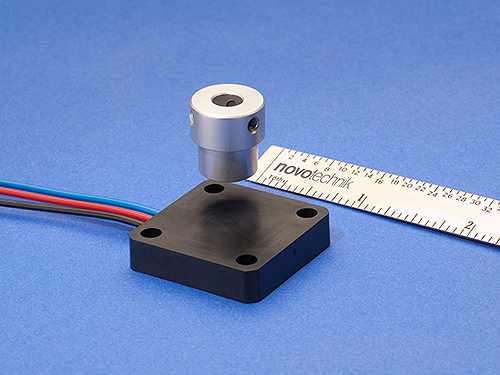

The RFA4000 Series features 12-bit resolution, compact size of 30x30x7mm3, unlimited mechanical lifetime and independent linearity within ±0.5%. A 14-bit SPI output version is also available. Repeatability is 0.1°. The housing is made of high-grade temperature-resistant plastic and is sealed to meet or exceed protection class IP67 and therefore not sensitive to dust, dirt, liquids or moisture.

The two-part design of the RFA4000 sensor and position marker offers engineers maximum flexibility when mounting the sensor. Since the sensor uses touchless technology with no shaft or bearings nominal application shaft offsets can be accommodated. Measurements can be made transmissively though various (non-magnetic) materials. Both leadwire and pc-board connection versions are available.

Custom versions of the sensor are available that are optimized for a specific angular range as well as custom magnetic markers with application-specific attachments.

Novotechnik

www.novotechnik.com

::Design World::

Filed Under: Sensors (proximity), SENSORS, TEST & MEASUREMENT

Tell Us What You Think!