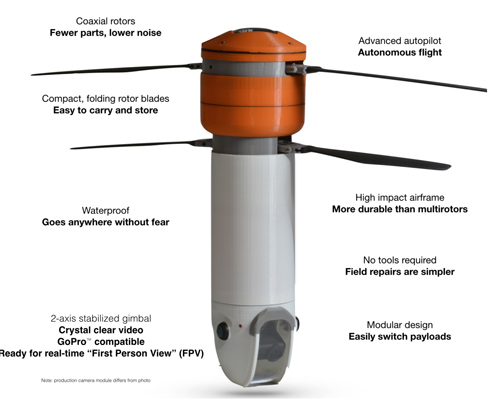

Small in size, the Sprite drone offers alternative to larger quadcopter drones

The developers of the Sprite, a small, durable drone that offers an alternative to larger, generally more fragile quadcopter drones, have received the latest Proto Labs Cool Idea! Award, a service grant given to innovative companies by quick-turn manufacturer Proto Labs, Inc.

The popularity of drone aircraft for consumer use is surging. More than 700,000 drones are expected to be sold nationwide this year, according to the Consumer Electronics Association. Drones are also getting lots of buzz as a hot holiday gift item this year.

“Drones are already playing key roles in a variety of industries, and for military and public safety applications,” said Proto Labs founder Larry Lukis. “This particular drone is innovative because of its consumer-friendly design: a smaller size, greater durability and ease of use.”

The Sprite Drone, developed by Arizona-based Ascent AeroSystems, is an ultra-portable drone that collapses to the size of a water bottle and uses a coaxial rotor design (two rotors stacked one atop the other).

Proto Labs’ Cool Idea! Award grant provided injection-molded parts for several iterations of prototype parts for the Sprite.

Jonathan Meringer, one of the founders of Ascent AeroSystems, said early Sprite concepts were developed on a consumer-grade 3D printer using PLA and ABS-like plastics. “While that was great for our initial development, that process didn’t provide the parts with the durability we required…the injection-molded polycarbonate parts (from Proto Labs) represent production-grade quality that’s added a dramatic improvement in everything from flight performance to assembly and maintainability. We were able to build several conforming vehicles that are really close to what the final product will be.”

The target market for the Sprite includes outdoor enthusiasts, such as hikers, backpackers and wilderness adventurers, though significant interest has also come from public safety, law enforcement, defense, security, scientific research and other commercial end-users, Meringer said.

Meringer says Q2 of 2016 is targeted for when the Sprite will actually reach the market. Current pricing begins at $699.

Ascent AeroSystems

ascentaerosystems.com

Proto Labs

protolabs.com

![]()

Filed Under: 3D printing • additive • stereolithography, Make Parts Fast