The National Composites Center near Dayton Ohio is taking a lead in composites and advanced materials structural design, optimization, and manufacturability simulation by offering all businesses accessibility and services to this resource. The new Center opens on May 6th. Interested parties can meet the staff and partners, and learn of the capabilities and opportunities that can move a business forward in composites simulation.

Shop floor processes can be simulated and improved upfront to reduce costly scrapping of parts, whether for lay-up simulation, laser projection, NC, tape laying or resin injection. Downstream activities for traditional hand lay-up include nesting, cutting and laser projection operations

The Center is a response to a call from the composites manufacturing industry. This resource will provide exposure and accessibility to design and simulation software capabilities creating an environment for composites experts, engineers, and technicians, throughout the composites supply chain – from materials suppliers to equipment manufacturers to end users of composite structures.

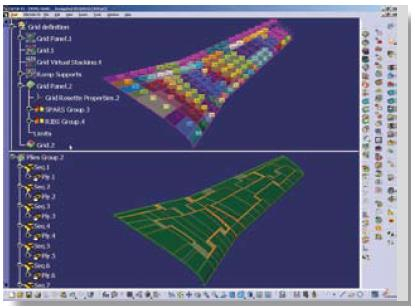

The goal of DS PLM integrated environment for Composites is to provide capabilities so designers can to work in a functional context, get accurate feedback from simulation and manufacturing, and even anticipate and avoid problems early in the process.

Design simulation software has always been difficult to justify from an ROI perspective. Small and mid-sized companies need technical expertise in addition to an investment in hardware and software. This presents a predicament for growing companies to consume the entire financial burden. The Center is intended to alleviate some of this burden by providing: a source, accessibility, training, incremental usage and access to experts (academia and industrial), and finally engineering communications with larger companies enhancing their capability to improve their design and manufacturing capabilities communications with their customers. The benefits of finding a design or manufacturing flaw through simulations can be enormous. The center also has the capabilities for large batch processing. For more details, contact Patti Johnson at: [email protected] or (937) 297-9454

Composites Manufacturing Design Center

compositecenter.org

::Design World::

Filed Under: Aerospace + defense, Software • 3D CAD, ENGINEERING SOFTWARE, Materials • advanced

Tell Us What You Think!