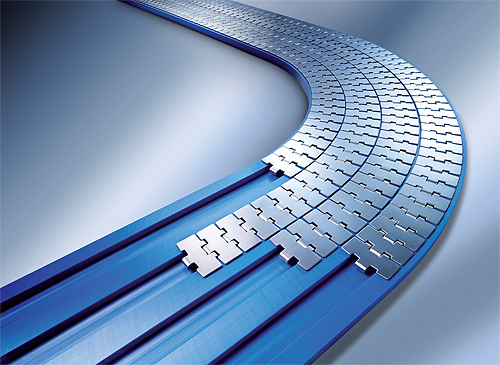

Keeping bottles and other products upright while conveying them throughout a warehouse or distribution center can be a challenge. This flat top chain can solve this issue. Magnetic curves for flat top chains, marketed under the Flexon brand, feature almost pulsation free running due to uniformly aligned magnetic fluxes throughout all tracks, thus conveying products for the beverage, food and packaging industries with low tensions and reduced noise.

Magnetic curves are plastic single or multi-track guides for flat top chains, which hold the chain in the curves while flexing around a radius by acting upon the chain pins with a series of magnets placed around the bend. When the pins transfer from one magnetic field to the next, the holding force is reduced and then increased again causing a slip stick effect. These vibrations can be transferred to the transported goods, and in the worst case, result in the goods tipping over.

With the Flexon magnetic curves, the slip stick effect has been reduced to practically zero by optimizing the arrangement of the magnets, adapting the magnetic field strength and increasing the size of the magnetic fields themselves. This enables products to be transported smoothly, with minimal jerking and much lower noise.

The magnetic curves reduce the forces created in the curves by as much as 60%. Consequently, the magnetic curves do not require as much driving power, so it is possible to run longer conveying systems with the same drive units. The arrangement of magnets is configured individually for each track according to pin diameter and chain pitch, which also achieves almost identical magnetic forces in each track. The magnetic curve track systems have good friction characteristics, ensuring that the flat top chains undergo low wear. Also reduced friction is one important factor – along with product stability, cleaning practices, and conveyor conditions – to achieving the desired goal of reduced lubrication or even dry running conditions.

The chain systems are made from top-quality, durable materials. Flexon magnetic curve systems are offered in all standard sizes and for all usual flat top chains, radii and angles. Standard Tab and Bevel curves are also available.

iwis drive systems, LLC

www.iwisusa.com

Filed Under: Conveyors, Belts + chains, Packaging

Tell Us What You Think!