The BattleBots competition has become a popular entertainment. But it is also an opportunity for engineers to hone their fast design practices and study failure analysis. One of the recent match winners of the current BattleBots season is Hal Rucker.

Hal Rucker and DUCK!

Photo courtesy of Battlebots.com

Rucker uses Protolabs to make custom machine keys, motor faces and mountings, and wheel guards. The sheet metal parts are brackets that hold the electronic speed controllers. All of the parts are made from aluminum.

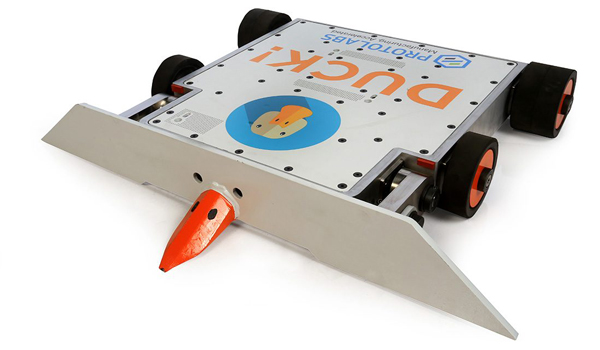

The DUCK! battlebot.

photo courtesy of Battlebots.wiki.com

Said Rucker, “I use Protolabs frequently when I’m making BattleBots and other projects when I need custom precision parts. Protolabs is incredibly fast, precise and reliable. I’ve been counting on them to deliver CNC, sheet metal and 3D printed parts for many years, and they’ve always done a great job. The engineers there were crucial to helping me build DUCK! in just 28 days, I couldn’t have completed the bot in time without their services and fantastic customer support.”

Filed Under: Flanges • supports • mounts • brackets