By Stephen Jackson, Business Development Manager of Thermal Managemenet, Sapa Extrusions North America

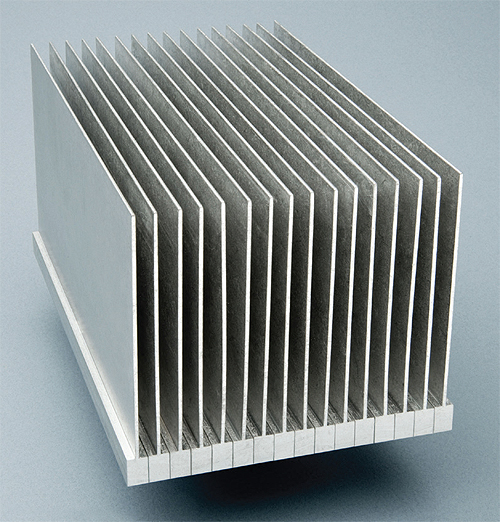

A recent innovation in aluminum extrusion offers a new way to produce higher ratio air-cooled heat sinks — heat sink ratios in excess of 40:1, and widths up to 30 in.

Aluminum extrusion at its most basic is the process of pressing logs of aluminum billet under extreme pressure through steel dies to create lengths of an extruded aluminum shape, or profiles. Innovation in aluminum extrusion often takes the form of process improvements or metallurgy developments that improve the speed and quality of the extrusion. However, a new process produces higher ratio air-cooled heat sinks from extruded aluminum profiles that can be particularly suitable for the lighting and power electronics industries.

While not a new process, friction stir welding is a solid-state joining method. It joins flush metal surfaces through the mechanical action of a rotating tool and produces high-strength, porosity-free, homogeneous joints that will not degrade over time. With the effects of pressure and heat, a new, homogeneous structure is achieved, with no filler material or insulators.

The options

With the rapid growth of LED lighting options and continual advances in consumer electronics, each year’s new products tend to bring increased energy demands, often in a smaller footprint. This presents a thermal management challenge since the heat produced by increased power can be highly detrimental to electronics.

Extruded aluminum heat sinks are the most common thermal management technology for cooling power electronic modules, followed by bonded fin heat sinks and liquid coolers (also known as cold plates), with each technology increasing in costs and complexity.

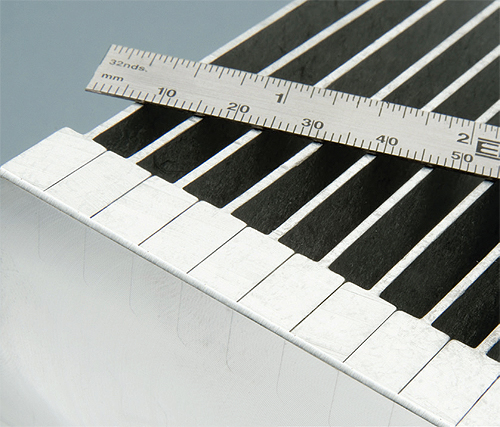

Extruded heat sinks fall into two categories: low fin and high ratios. The fin ratio is the height of the fin compared to the width in between the fins. Typical aluminum extruders can provide ratios of 6:1; however, that does not meet the requirements of most power electronics. Currently, typical power electronics require ratios in the range of 12:1 to 19:1. The greater the fin ratio, the greater the surface area. The greater the surface area, the larger the amount of heat that can be removed.

To extrude higher ratios requires specific extrusion technology and experience. But it is difficult to extrude very wide heat sinks, and nearly impossible to find extruded heat sinks wider than 24 in. However, the advantage of extruded heat sinks is that this thermal device is made of one solid piece of aluminum, eliminating any insulators, which aids thermal efficiency. Additionally, most applications for extruded heat sinks can use natural convection, meaning no fans are needed.

When higher ratios are required by higher power applications, bonded fin heat sinks (thermal epoxy or brazing) with a higher fin aspect ratio are generally used to overcome fin ratio limitations of the extrusion process (typically 19:1). Bonded fin heat sinks typically involve the use of thermal epoxy to bond a coil of aluminum-to-aluminum extrusions or plates. A groove typically must be cut into the plate, and then the aluminum coil is manually attached to the base.

The friction stir welding process starts with extruded segments that include a base and a fin. Then, the process permanently joins the segments. The extruded segments can be any extrudable profile and dimension.

Our friction stir welded (FSW) modular heat sinks offer a different approach that is 8% more thermally efficient than bonded fin heat sinks and has more options, such as custom features that reduce assembly costs. Combining the extrusion process with friction stir welding technology, we can achieve heat sink ratios in excess of 40:1. The combination of FSW with extrusions allows for maximum flexibility when it comes to fin geometry and fin ratio, as well as heat sink footprint and easier production of large scale heat sinks (30 in. width). The friction stir welding process is also used in liquid cold plates to efficiently seal the cold plate while allowing more features to be added to the base plate, at a lower cost.

Advantages of friction stir welding compared with fuse welding include:

• Increased strength

• Homogenous material, no filler metal or insulators

• Increased impermeability – entirely nonporous, sealed joints

• Joints flush with the surface

• Reduced thermal deformation – only minor thermal stresses in the material, and consequently, flat surfaces

• Greater repeatability – production has few and easily controlled variables, which also creates close tolerances

A novel method of joining metal surfaces

Friction stir welding is a solid-state joining method that has been used in the welding of aluminum since the 1990’s. It joins flush metal surfaces through the mechanical action of a rotating tool and produces high-strength, porosity-free, homogeneous joints that will not degrade over time. With the effects of pressure and heat, a new, homogenous structure is achieved, with no filler material or insulators.

Rather than manually join aluminum coil to an aluminum base with thermal epoxy, custom aluminum extrusions replace the coil aspect of the bonded fin heat sinks. They are friction stir welded together without the need for a separate base plate.

The process starts with extruded segments that include a base and a fin, which are held together by clamping and punching. The heat sink is joined permanently by FSW. Because the extruded segments can be any extrudable profile and dimension, there are fewer limits in the design. For example, the segments could be 10 in. tall. Not only does this method allow for the production of large-scale heat sinks up to 20 in. in width or more, it is also well-suited for serial production, making these types of heat sinks a competitive product in the marketplace.

While extruded heat sinks up to ratios of 19:1 were common in the United States, many companies in the power industry needed greater ratios. At the same time, the LED light industry was looking for extrusions larger than the typical 20 in. maximum extrusion width. Friction stir welded modular heat sinks solved both problems.

Friction stir welding enables the production of large-scale heat sinks up to 20 in. in width or more.

Test results

The tests of a friction stir welded modular heat sink versus an epoxy bonded fin heat sink show the improvement in cooling offered by FSW technology. The heat sink’s dimensions and fin aspect ratio were designed to be suitable for extrusion, and an extruded heat sink was used as the benchmark. The experiment was carried out in a wind tunnel with various airflows. Power resistors were used as heat sources. Thermal resistance, pressure drop, and temperature distribution were obtained and compared. The result was an 8% increase in thermal performance over the epoxy bonded fin heat sink while maintaining an equivalent pressure drop.

The 8% increase in thermal efficiency gives the power electronics designer two options. The first is the ability to increase the amount of power the electronics generate without increasing the size of the heat sink. The second is to decrease the size of the FSW heat sink by 8% and still provide the same thermal management. Either option helps reduce the cost of the heat sink.

Many times the technology to manufacture new products is even more advanced than the product itself. In the case of extruded aluminum, understanding the material alone is often not enough for engineers and designers to take full advantage of aluminum’s versatility. Innovative processes like friction stir welding, along with alloy developments and extrusion process advances, must also be understood to appropriately choose the most effective material or product solution.

Friction stir welding technology is not all that new and has been used by different industries for years. It is not as well known as it could be because it is a proprietary licensed process and uses automated equipment not typically found at traditional weld shops. Extending friction stir welding technology to develop a solution for the thermal management arena has resulted in this innovation, which offers an exciting answer to one of the power electronics industry’s big challenges.

Sapa Extrusions North America

www.sapagroup.com

Filed Under: Materials • advanced

Question: Can the same heat sink that displaces heat, also concentrate and magnify heat?