By Leslie Langnau, Managing Editor

Tom Corey thought he had a better idea for the motion control marketplace. So in 1990, he founded his linear motion components distributorship, Specialty Motions, Inc., (SMI) in California. The market responded as he had foreseen, choosing the price, quality and performance users needed from his broad array of slide bush products, slide guides, ball splines, slide shaft, slide way and slide table products.

Next SMI started to combine components into assemblies for its clients, which led to experimentation with the linear motion products it carried. Soon the engineers found slide bush components with unique characteristics that ensured simple motion control solutions would be reliable and easy to maintain.

When a client needed an inexpensive, easy to maintain X/Y system, for loading material into a printing system, SMI engineers were able to deliver. They attached aluminum pillowblock slide bush components to a custom machined metal plate. To ensure fast, smooth operation, they chose a slide bush with precision ground raceway surfaces. Since the contact areas between the ball elements and the raceway surface of the slide bush were minimized, the slide bush exhibited minimal friction. Twin slide bushings with seals at both ends were used. The seals prevent dust from entering the slide bush, ensuring motion accuracy. The outer cylinder of this standard type slide bush is made of bearing steel and resin. Its open type housing allows a support from below so that shaft deflection is minimized for high loading or long-stroke applications.

Tom Corey explained his choice, “If something were to happen – say a bearing wears out over time, it is so easy to replace them inside an NB Corporation pillowblock. With NB, all you do is take four fasteners off the bottom, remove a skip plate and the old bearing slides out. You put the new bearing in place, put four fasteners back in and you’re off and running again.”

Another inexpensive custom solution gave a different client the linear/rotational movement he needed – the ability to move X as well as Theta. The engineers put a flat washer on a slide bush, slipping a needle bearing on the outside of the smooth steel housing, then putting another flat washer on the top. The engineers chose this particular slide bush because there is a ring groove at the end of it. Said Corey, “The NB SW8 type was best suited to the application. It is smooth on the outside, very round and very hard. It lent itself to be a perfect bearing surface.”

Consistency problems plagued a manufacturer of spectroanalyzers. The cause was the analyzer’s cartridge bearing used to position samples. The cartridge bearing, which was in a bore, was not stable while the machine was running, rendering measurements inaccurate. This bearing was composed of a thin walled tube with two bearings in it. The ends of the tube were crimped. The walls were just too flimsy to provide the needed stability.

To solve the problem, SMI engineers used a doublewide slide bush that has a resin retainer. It incorporates two bearings in a single container that keeps everything aligned. In addition, it was less expensive than the cartridge bearing it replaced. The double width slide bushings were specified for their greater load capacity – necessary especially because a moment load was to be applied. For moment load, double or triple wide type slide bushings are recommended.

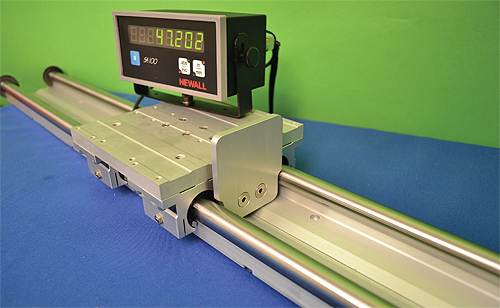

Finally, SMI engineers needed to measure long materials, such as shafts, right at the shop floor. The materials being measured could be round, flat or square material, with lengths longer than the typical vernier caliper could measure at a reasonable cost. To construct the measuring device, they used the open pillowblock slide bush type TW8UU, part of NB’s TOPBALL self-aligning slide bush line. TOPBALL’s floating wiper seal makes this unrestricted self-alignment possible.

The engineers combined a half-inch slide bush with a shaft and a linear Digital Read Out (DRO). The slide is 120 in. long. By sliding the carriage all the way to the end, the DRO is reset to ‘zero’. As the carriage is moved out, the DRO reads where the carriage is relative to the end plate. The DRO display can be mounted to the carriage itself or fixed in a different location for convenience and protection. The Linear Digital Measuring Device (LDMD) is capable of accuracies up to +/- .001 in. and any length up to 110 in.

NB’s slide bushings are available in an array of configurations. Their wiper seals are high quality precision grade. Choose from single, double wide, or center mount. They are available in inch, Asian or European metric dimensions. The three shaft grades have diameters ranging from 3.175 mm – 50.8 mm; .125 – 2 in. Slide bush lengths range from 12.7 mm – 203.2 mm; .5 – 8 in.

NB Corporation of America

www.nbcorporation.com

Filed Under: LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!