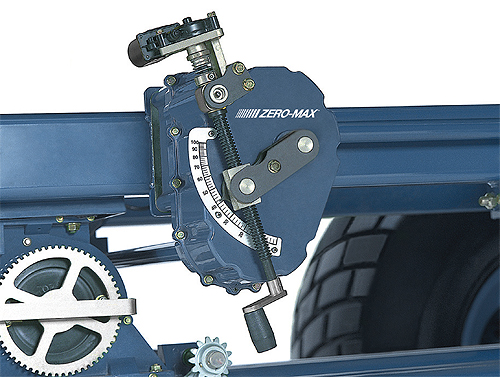

Precision farming management relies on observing and responding to intra-field variations. The concept uses new technology such as geospatial tools coupled with innovative agricultural equipment that maximizes returns on inputs while preserving resources. When integrated into the newest agricultural equipment, Custom Variable Speed Drives from Zero-Max make precision farming more efficient and profitable.

The drives meter and dispense seed and fertilizer guided by global positioning systems. Designed for the latest precision farming equipment, these custom drives provide accurate and repeatable settings to optimize the seeding and fertilizing process.

The drives are used as a prime mover connected to a motor, or as a secondary drive connected to a shaft in the machine’s driveline. When used as a prime mover, the drive acts as a variable speed device. When used as a secondary drive, it becomes a variable ratio device. The drive permits slow or fast, small or large speed changes.

The variable speed feature enables more accurate settings for the map-based feeding and seeding process. For example, the drives can be designed to accommodate varying terrain and soil conditions where real-time changes in fertilizer output are required. (Example: vary fertilizer application from 15 pounds per acre to 40 pounds per acre or any prescribed rate). For seeding, the drives are flexible, reliable and precise to help accommodate the narrow time-window for best seeding and for different application rates needed for seeding corn, wheat, oats and other crops.

Zero-Max

www.zero-max.com

Filed Under: Drives (ac) + VFDs + starters, Drives (dc), Off highway • construction • agriculture

Tell Us What You Think!