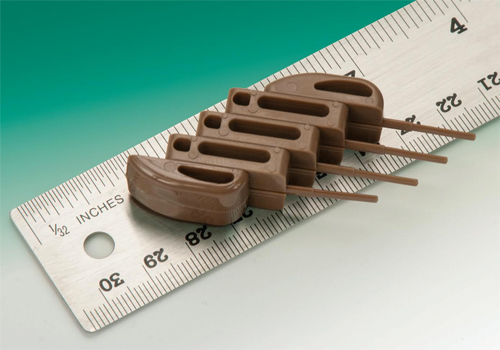

Medical components custom molded of PEEK from Minnesota Rubber and Plastics (MR&P) improve performance while reducing costs. The company has proven experience molding PEEK designs that dramatically increase product performance and provide a superior alternative to metal and glass components.

PEEK (polyetheretherketone) is a high performance thermoplastic. Utilizing MR&P’s proprietary processes and designs, PEEK can be used as an alternative material to provide long operating life with chemical resistance. PEEK has excellent retention of mechanical properties in high heat applications up to 570°F (300°C). PEEK components also are highly resistant to thermal degradation as well as attack by both organic and aqueous environments.

“Increasingly rigorous performance requirements for new medical equipment and device designs require the utilization of alternate materials,” reports Aron Yngve Medical Market Director of Minnesota Rubber and Plastics. “PEEK is ideal for robust applications in medical appliances, medical pumps, IV systems, feeding devices and both implantable and non-implantable medical devices. PEEK is particularly useful where fluid isolation is required by the seal design.”

“Increasingly rigorous performance requirements for new medical equipment and device designs require the utilization of alternate materials,” reports Aron Yngve Medical Market Director of Minnesota Rubber and Plastics. “PEEK is ideal for robust applications in medical appliances, medical pumps, IV systems, feeding devices and both implantable and non-implantable medical devices. PEEK is particularly useful where fluid isolation is required by the seal design.”

PEEK is one of many high performance materials utilized by MR&P in its designs for the medical industry. Others include compounds compliant with ISO 10993, USP Class VI, and FDA requirements. In addition to materials engineering from a broad range of medical grade material options, MR&P provides product design assistance.

MR&P operates an ISO 13485:2003 certified quality management system and manufactures medical seals in Class 10,000 and Class 100,000 clean rooms. MR&P’s precision molding capabilities are comprised of silicone molding and bonding, processing of high-performance rubber and plastics, rubber-to-plastic conversions, and metal-to-plastic conversions, in addition to manufacturing components and seals. The company is experienced in the manufacture of complete medical device products involving complex assembly through final packaging.

Since 1945, Minnesota Rubber and Plastics has built a world-wide reputation founded on a unique, science-based approach that has made the company a preferred manufacturing partner for medical and pharmaceutical industry leaders in North America, Europe and Asia.

MR&P’s global, large-scale manufacturing facilities are based in five countries with capabilities to handle the largest volumes including multi-year partnership contracts. The company’s experience and unique ability to offer both rubber and plastic combination medical device assemblies result in greater engineering design and production efficiencies. These advantages result in reduced development time, reduced costs and decreased time-to-market.

Minnesota Rubber and Plastics

www.mnrubber.com

Filed Under: Medical-device manufacture, MOTION CONTROL, MORE INDUSTRIES

Tell Us What You Think!