Schaumburg, IL–Omron Electronic Components LLC is offering custom calibration and bypass design assistance for flow sensing applications to customers whose requirements are not quite suited for off-the-shelf product. This free design assistance is available whether you require a few hundred or several thousand.

Most of Omron’s standard mass flow sensors are calibrated for AIR, except for the D6F-05N/L series which have Natural Gas and Propane calibrations. For those customers who want to measure other (non-corrosive) gases, the Omron factory team is able to assist with custom calibrations. Each request is evaluated to determine if adequate engineering resources are available and to provide customers with lead-time for initial evaluation units.

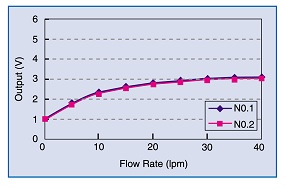

Since the thermal properties and densities of different gases vary, the output curves for them will vary as well. To optimize the output with some gases, minor circuitry adjustments to the sensors may be required (see Figures 1 and 2).

Figure 1: Sensor output when Helium gas is used with a standard D6F-05N. Notice, the curve is too flat from 20 to 40 LPM.

Figure 2: Sensor output when Helium gas is used in a modified D6F-05N. Notice, the improved resolution.

Other gases are similar enough to air that a new output curve is all that needs to be provided. Gases for which custom calibration is possible include (though not necessarily limited to) Argon, Helium, Heliox, Carbon Dioxide, Nitrogen, Natural Gas, Propane, Nitrogen Oxides, and Oxygen.

A bypass set-up is a cost effective means of measuring large flows with a low flow rate sensor (see Figure 3).

To assist with the bypass design, Omron’s Engineering Department will run a basic analysis utilizing their Computational Fluid Dynamics (CFD) software to provide customers with a starting point for their design. The process is started by providing some of the basic system parameters such as type of gas, flow rate range, Omron part number, main flow path dimensions, and the bypass tube dimensions. It should be noted that the CFD analysis provides an estimate for ideal conditions which the customer should then test to verify or adjust based on actual conditions.

::Design World::

Filed Under: SENSORS, TEST & MEASUREMENT, ELECTRONICS • ELECTRICAL

Tell Us What You Think!