The most basic definition of a direct-drive motor is a type of design that allows the motor to be connected directly to the driven load. Doing so eliminates mechanical transmission elements that tend to add compliance into a drive system such as gears, couplings, belts and pulleys, and chain drives. Direct-drive motors are sometimes also referred to as torque motors, Lorenz-force motors or pancake motors.

A traditional motor and drive setup on the left shows some of the mechanical drive components such as a gearbox and drive gear that are eliminated in the direct-drive motor on the right. (Image courtesy of Zettlex)

A typical rotary direct-drive motor, such as this housed servomotor from Kollmorgen, offers higher torque density and more precision than a non direct-drive servomotor. (Image courtesy of Kollmorgen)

Eliminating these components can significantly improve system performance in several key ways. For instance, by reducing maintenance, improving load acceleration, lowering power consumption, and reducing system inertia and boosting precision.

One of the most common types of motors used in direct-drive setups is a brushless permanent-magnet synchronous motor. Often the axial height of these motors will be shorter than the motor diameter, hence the alternative name “pancake” motor. These types of motors also typically have a large center through-bore.

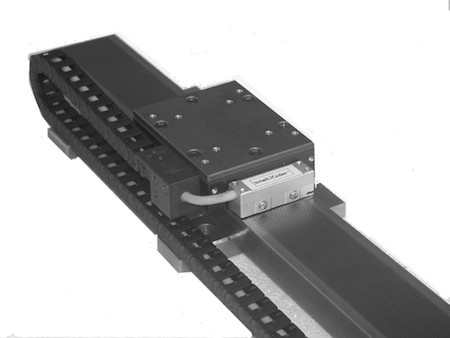

Variations of these motors can be defined in several ways. For instance, there are both rotary as well as linear direct-drive motors, though designers may be more familiar with the rotary type because they are more common and more closely resemble traditional rotary motors. As for linear direct-drive motors, one way to think of them is as a rotary motor that is cut open axially, rolled out flat and connected directly to the load.

Direct-drive linear actuators, such as these units from IntelLiDrives, feature a direct-drive linear motor with mechanical bearings and a moving carriage. (Image courtesy of IntelLiDrives)

Another way to classify direct-drive motors is by whether or not they’re enclosed. For instance, housed motors are enclosed within a motor frame. There are also un-housed, or frameless, motors. These motors may be offered without bearings or sensors of any kind and get integrated directly into a machine.

Filed Under: Motors (direct-drive) + frameless motors, Motion Control Tips

Tell Us What You Think!