Making electric cars lighter also involves reducing the weight of the motor. One way to do that is by constructing it from fiber-reinforced polymer materials. Researchers at the Fraunhofer Institute for Chemical Technology ICT are working together with the Karlsruhe Institute of Technology KIT to develop a new cooling concept that will enable polymers to be used as motor housing materials. And that’s not the only advantage of the new cooling concept: it also significantly increases the power density and efficiency of the motor compared to the state of the art.

The two key components of an electric drive train are the electric motor and the battery. And there are three issues that play a particularly important role when it comes to using an electric motor for eco-friendly mobility: high power density, a compact configuration that fits snugly within the electric vehicle, and high levels of efficiency. As part of the DEmiL project – a German abbreviation that stands for directly-cooled electric motor with integrated lightweight housing – researchers at Fraunhofer ICT in Pfinztal are now working with the Institute of Vehicle System Technology (FAST) and the Institute of Electrical Engineering (ETI) at Karlsruhe Institute of Technology KIT to develop a novel approach that incorporates direct cooling of the stator and rotor. “An electric motor consists of a rotating rotor and a static stator. The stator contains the copper windings that the electricity flows through – and this is where the majority of electrical losses occur. The novel aspects of our new concept lie in the stator,” says Robert Maertens, a researcher at Fraunhofer ICT.

Rectangular flat wire replaces round wire

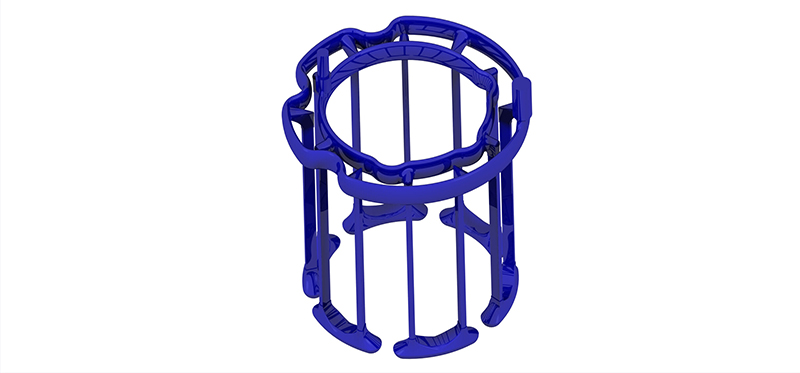

Electric motors have a high efficiency of over 90 percent, which means that a high proportion of the electrical energy is converted into mechanical energy. The remaining 10 percent or so of the electrical energy is lost in the form of heat. To prevent the motor from overheating, the heat in the stator is currently conducted through a metal housing to a cooling sleeve filled with cold water. In this project, the team of researchers have replaced the round wire with rectangular flat wire that can be wound more tightly in the stator. This creates more space for the cooling channel next to the flat wire winding phases. “In this optimized design, the heat losses can be dissipated through the cooling channel inside the stator, eliminating the need to transport the heat through the metal housing to an exterior cooling sleeve. In fact, you no longer need a cooling sleeve at all in this concept. It offers other benefits, too, including lower thermal inertia and higher continuous output from the motor,” says Maertens, explaining some of the advantages of the new system. In addition, the new design incorporates a rotor cooling solution that also allows the rotor’s heat loss to be dissipated directly within the motor.

By dissipating the heat close to where it is generated, the project partners were able to construct the entire motor and housing from polymer materials, leading to further advantages. “Polymer housings are lightweight and easier to produce than aluminum housings. They also lend themselves to complex geometries without requiring post-processing, so we made some real savings on overall weight and cost,” Maertens says. The metal currently required as a heat conductor can be replaced by polymer materials, which have a low thermal conductivity compared to metals.

The project partners chose to use fiber-reinforced, thermosetting plastics that offer high temperature resistance and high resistance to aggressive coolants. Unlike thermoplastics, thermosets do not swell when they come into contact with chemicals.

Suitable for large series production

The polymer housing is produced in an automated injection molding process. The cycle time for manufacturing the prototypes is currently four minutes. The stators themselves are overmolded with a thermally conductive epoxy resin molding compound in a transfer molding process. The team of researchers chose a design and manufacturing process for the electric motor that will allow it to be mass-produced.

The team has already completed the stator assembly and experimentally validated the cooling concept. “We used an electrical current to introduce the amount of heat in the copper windings that would be generated in real operation according to the simulation. We found that we can already dissipate over 80 percent of the expected heat losses. And we already have some promising approaches for dealing with the remaining heat losses of just under 20 percent, for example by optimizing the flow of coolant. We are now at the stage of assembling the rotors and will soon be able to operate the motor on the test bench at the Institute of Electrical Engineering and validate it in real operation,” says Maertens, summing up the project’s current status.

Coolant circuit in the stator. Credit: Fraunhofer ICT

Filed Under: Product design