By Evan Yares, Senior Editor & Analyst, Software

Why you may—and may not—want to consider an integrated solution.

There’s a simple question you can answer that will help you figure out whether you should consider using an integrated CAD/CAM system: Is your current CAM system the biggest source of frustration in your work life?

If it isn’t, then no problem. If it is, then you should take a careful look at integrated CAD/CAM. But probably not for the reason you think.

There are, broadly, two types of integrated CAD/CAM systems: CAD-centric ones, which are designed for people (or companies) that have standardized on a particular CAD system, and want the benefits of compatibility and associativity that integrated CAM can bring, and CAM-centric ones, which are designed for NC programmers who need CAD functions to do their work more efficiently.

The difference in centricity is a qualitative thing, and comes largely from the focus of the vendors who create the software, and the worlkflow in which the software is used.

CAD-centric

If you’re using SolidWorks with an integrated CAM system, you know what CAD-centric is. It’s when a CAM program is run on top of (or inside of) a CAD program, using the CAD program’s API (application programming interface.)

SolidWorks is probably the best example of a CAD program which supports API integration of CAM. Though Dassault Systemes SolidWorks Corporation doesn’t sell CAM software itself, no less than 14 different CAM companies offer either “Certified Gold” or “Certified CAM” partner products for SolidWorks. To gain either of these levels of certification, a CAM program must be fully integrated and associative with SolidWorks, and must undergo certification testing. Gold certified programs must additionally provide “single window” operation, running inside the native SolidWorks user interface.

Delcam is a company that offers both certified CAM and certified gold products for SolidWorks. FeatureCAM is a standalone CAM program for milling machines, turning and turn/mill centers, and wire EDMs. Delcam has connected FeatureCAM with SolidWorks through API integration. Delcam for SolidWorks is an integrated CAM system, based on FeatureCAM and PowerMill technology, which runs completely inside of the SolidWorks assembly environment.

For NC programmers, certified gold and certified CAM products offer distinctly different experiences. Certified gold products are particularly appropriate for workflows that are limited to native SolidWorks part and assembly files, and are ideal when the CAD designer and NC programmer are the same person. They do impose some knowledge overhead, as users must learn SolidWorks in addition to the CAM program.

Certified gold CAM programs, although they run inside of SolidWorks and use SolidWorks user interface conventions, do not necessarily behave in the same way that a SolidWorks native CAM program would (if such a program existed.) Independent CAM developers bring their own way of doing things to their programs. Often, when integrating their software with SolidWorks, they start with pre-existing components and object models, which have to be adapted to work in the SolidWorks context. The result is that some certified gold CAM programs don’t really have an entirely SolidWorks-like feel in use.

For multi-CAD workflows, where the NC programmer receives data in a variety of formats (not just SolidWorks), certified CAM products are often a better choice than certified gold products. This has to do with two things: First, a certified gold program generally uses SolidWorks’ import facilities, while a certified CAM program will generally have its own import facilities—which will be designed to work better with poor quality (e.g., not watertight) CAD files. Second, SolidWorks’ tools for cleaning up and repairing poor quality imported CAD data are not a match for those of the best standalone CAM programs (several of which are certified CAM partner products.)

Certified gold products and certified CAM products from the same vendor often vary in capabilities. But it’s not a rule that one is more capable than the other. It’s something that varies vendor by vendor, and product by product.

CAM-centric

Traditionally, CAM-centric integrations have come from CAM vendors who have added limited CAD functionality to their software.

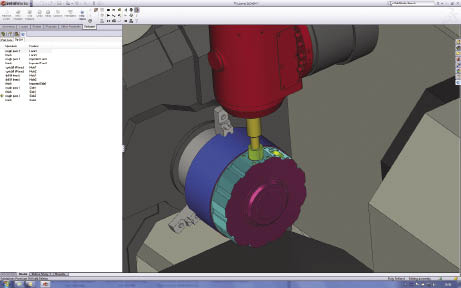

Cimatron is a good example of this approach. In the CimatronE 5-axis machining application, the built-in CAD mode is focused on surfacing tools to allow correction of geometry issues on imported CAD data, and to optimize machining. In the CimatronE mold design application, additional CAD capabilities are included, for designing and documenting mold tools. So, in both cases, the CAD capabilities of the program are tuned to the needs of the processes for which they’re used. They’re not a replacement for standalone CAD programs.

A different approach to CAM-centric integration is to combine full-function CAD with full-function CAM—but rather than doing it through an API, where one program must work with the other’s data model, it’s done with direct source-code integration, using a common data model.

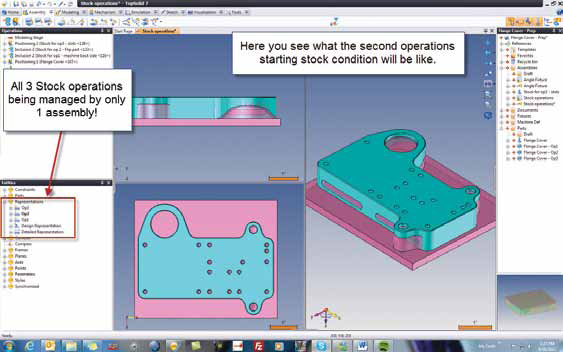

An interesting example of this form of integration can be found in TopSolid, from Missler Software. TopSolid was originally designed by a company that built machine tools, and was, from the start, an integrated CAD/CAM program.

The important characteristic of TopSolid is that it is neither a CAD program with CAM bolted on, nor a CAM program with a limited set of CAD capabilities. TopSolid is a full-function integrated CAD/CAM system, with capabilities and usability that are a match for many best-in-class CAD and CAM programs.

Missler has accomplished this by periodically re-thinking and re-writing the software, based on a new and clean architecture—a process that not many CAD/CAM developers undertake. The newest version of TopSolid is written using C# and the Microsoft .net framework, and provides significant support for multi-core processors. While the new TopSolid architecture allows improved usability and performance, the most important thing it does is allow truly native—and transparent—interoperability of CAD and CAM functions through a common data model.

Another example of CAD-centric integration, at the far end of the spectrum of CAD capabilities, is NX CAM, from Siemens PLM.

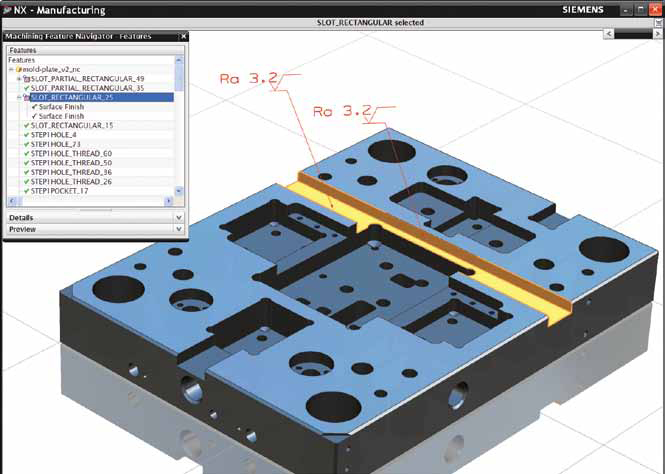

NX CAM supports the use of product and manufacturing information (PMI) to automatically machine features. PMI data can be imported from other CAD systems, or created in NX.

NX is Siemens PLM’s enterprise CAD/CAM solution, created by merging Unigrahics, and SDRC I-DEAS. It consists of a large number of integrated modules, designed to handle any problem that might be thrown at it, in the most demanding of applications. NX CAM is available in a variety of configurations, but the most popular come with a very full set of NX CAD functionality, including Synchronous Technology, Siemens PLM’s proprietary direct modeling technology.

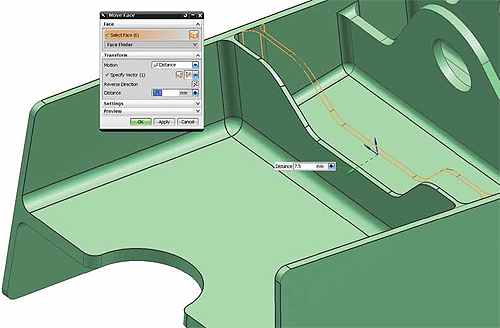

If one thing that has changed NX CAM from being just a big complicated CAM program to being a big complicated and highly usable CAM program, it is the inclusion of Synchronous Technology. Sync Tech (as it’s called) allows NX to intelligently edit CAD models and assemblies imported from other systems—notably Pro/E and CATIA. And it allows NC programmers to easily make changes to either native or imported files, without needing to know how they were built.

An example of a capability enabled by the integrated CAD/CAM functions in NX is the creation and maintenance of stage models, based on a common master model. Stage models are 3D representations of the part at each stage of the machining process. These can be used for inspection, documentation, fixturing design, and more. They’re associative to the master model, and update when it changes.

Direct editing tools, such SolidWorks user interface conventions, do as NX CAM’s Synchronous Technology, allows easy modification of 3D geometry, even on dumb imported solids.

Another core strength of NX CAM is in supporting model-based development, with semantic PMI. NX can read PMI data from CATIA and Pro/E files, but can also add PMI to imported data that doesn’t already include it. PMI can be used to drive automated NC programming and for CMM inspection programming.

NX CAM offers an an almost embarrassing amount of CAD/CAM capability—to the point where many users don’t recognize all the potential in their software.

TopSolid and NX CAM, though very different programs, share a few important characteristics that make them stand out from the crowd: First, they’re strong CAM programs. Second, they include full-function CAD capabilities, with direct editing tools. And third, they’re integrated at a source-code level.

Should you change?

The question of whether you should consider using an integrated CAD/CAM system has a lot to do with your current situation, and what particular integrated CAD/CAM system you’re considering.

If you’re using SolidWorks, or another CAD system which supports API integrated CAM, then you should absolutely have a look and see if the benfits of an integrated solution might make your life better.

If you’re using a standalone CAM program, and find yourself pulling your hair out when using it, you should definitely look at a modern integrated CAD/CAM solution—preferably one with full-function CAD and flexible direct editing.

TopSolid’s advanced software architecture allows it to manage multiple stock operations in a single assembly.

A business perspective

I spoke with Jeanne Naysmith, of the industry analyst firm Cimdata, to get his thoughts on integrated CAD CAM. He pointed out that the first consideration, when looking at CAM software, should be the goals of the business owner.

For many companies, CAM is used as part of well defined and repetitive processes. Change to those processes involves risk.

One of the significant considerations when looking at new CAM software is the question of who will be running it. NC programming has a rather tradesman-like quality to it, combining a theoretical knowledge of machining with a practical knowledge of the intricacies and quirks of individual machines and processes. The knowledge and skill an NC programmer gains from working with a particular CAM product can be difficult to transfer to another CAM product.

Naysmith also raised an interesting question about the selection process for new CAM software: Who will select it? The smartest person on the team, or an average person? This makes a difference if you’re looking for real-world productivity and efficient utilization of resources in the organization.

Reducing business risk is a key requirement, according to Naysmith. He recommends that companies start a separate initiative to evaluate new CAM software, while leaving the existing CAM tools and processes in operation..

Discuss this on The Engineering Exchange:

SolidWorks

www.solidworks.com

Delcam

www.delcam.com

Cimatron

www.cimatron.com

Missler Software

www.topsolid.com

Siemens PLM Software

www.siemens.com/plm

CIMdata

www.cimdata.com

Filed Under: Software • 3D CAD, Software • CAM, ENGINEERING SOFTWARE

Tell Us What You Think!