Dorner’s facility in Jülich, Germany (Dorner Europe) is again expanding by now manufacturing 2200 Series Modular Belt conveyors.

Dorner is an industry leader in the design, application, manufacturing and integration of precision industrial and sanitary conveyor systems.

The 2200 Series Modular Belt is ideal for small to medium part handling within the automation, packaging, assembling, metalworking and general manufacturing industries. The conveyor comes with features and benefits that make it the go-to choice for conveying applications, including:

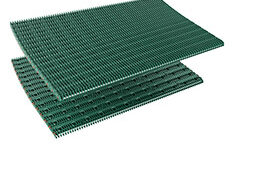

- Ladder-style, open-frame design that allows better airflow through the frame for cooling, water and chemical drainage applications

- Sleek, narrow profile for positioning under machinery and in other tight spaces where other conveyors wouldn’t fit

- Universal T-slot compatible with industry standard hardware for attaching accessories and guiding fast and simple

The 2200 Series Modular Belt Conveyor comes with an optional high-speed nose bar transfer option for safe and efficient transfers of small parts at speeds up to 175 ft per min. Customers can choose from two styles of plastic chain belting: micro pitch, general purpose modular belt or a metalworking modular belt (1 in. or 2 in. cleats are available on the metalworking modular belt).

Features and specifications of the 2200 Series Modular Belt conveyor include:

- Loads up to 150 lb

- Belt speeds up to 250 ft per min

- Belt widths: 3 in. to 24 in.

- Conveyor lengths: 18 in. to 30 ft

- Micro pitch (general purpose) belt option

- Metalworking belt option

- 12-mm diameter integral drive shaft

- Fully encapsulated in frame belt return

Now building three versions of the 2200 Series in Germany enables customers throughout Europe and the Middle East to take delivery of their equipment faster than ever before.

For more information, visit dornerconveyors.com, or connect with them on Facebook, Twitter, YouTube or LinkedIn

You may also like:

Filed Under: Belts + chains