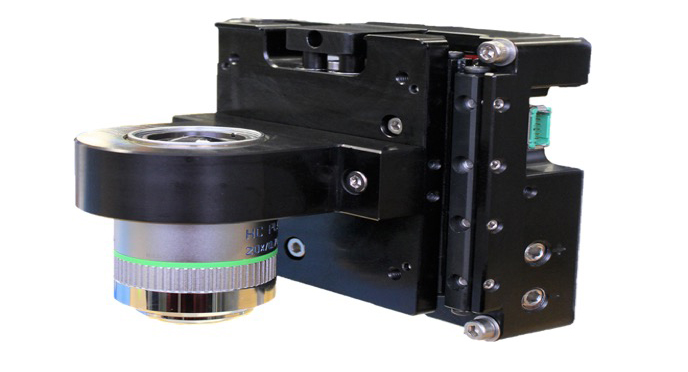

Dover Motion, a designer and manufacturer of motion setups for life sciences and diagnostics instruments, today announced the launch of the DOF-5 Objective Focusing Stage. The DOF-5 is a microscope objective nanopositioning stage optimized for optical imaging applications.

Developed for automated microscope objective focusing applications including next-generation sequencing (NGS), digital cell morphology, and automated digital pathology, the DOF-5 is a demonstration of Dover Motion’s commitment to introducing disruptive innovation into the life sciences and diagnostics industries. The DOF-5 introduces many new features such as greater travel (> 5 mm) and performance improvements over piezo stages. These features are enabling product developers to reach product performance gains, while the lower product cost is revealing new market, product and application opportunities.

“We are confident the DOF-5 will deliver significant performance advantages for focusing platforms in automated digital microscopes,” said Ankush Kaul, vice president and general manager of Dover Motion. “We’ve developed a low-cost technology setup that provides enhanced integration features, higher precision and repeatability, and many additional benefits that were requested by the customers.”

The fundamentals of the DOF-5 were guided by Voice of Customer research. In interviewing numerous original equipment manufacturers (OEMs), opportunities and insights were identified and translated into product requirements to deliver a more flexible objective focusing stage. The resultant DOF-5 exceeds the performance characteristics of typical piezo-based stages and includes the following additional features and functionality:

- crossed roller bearings to remove common issues of flexure bearings which can be susceptible to off-axis motion;

- optical position feedback and servo drive controls integrated directly into the stage;

- embedded controller to reduce system complexity;

- inbuilt design features such as side mounted user adjustable hard stops to precisely set the objective travel and prevent collisions; and

- increased travel (up to 5mm), with higher bandwidth and fast step and settle to provide more engineering flexibility.

“Dover Motion’s DOF-5 provides a great setup for single high numerical aperture microscope objective actuation,” commented Tedd Kelemen, vice president of sales and marketing at WDI Wise Device Inc., a manufacturer of compact autofocus sensors, automated microscopy modules and end user infrared imaging systems. “It provides all the benefits of piezo regarding speed and resolution, but with none of the limitations such as short travel range and ringing, at a lower cost.”

“Many automated microscopy applications still rely on lever-amplified piezos with flexural guideways for objective focusing, despite their disadvantages,” added Kevin McCarthy, chief technology officer at Dover Motion, in discussing the advantages of the DOF-5.

“In developing the DOF-5, we overcame the limitations through the application of stiff, crossed roller guideways, combined with an integrated servo drive to provide dramatically increased travel, much higher stiffness, and far shorter move and settle times.”

Dover Motion is offering demonstration units of their DOF-5 stage to interested OEMs to test and assess performance capabilities within their instruments. Request a demo unit.

Dover Motion is a leading provider of precision stages and engineered motion setups for the medical, life sciences, and diagnostics industries. With over 50 years of industry experience, the company’s core strength lies in designing custom engineered motion systems and modules. The company also provides standard products using lead screws and ball screws, belts and pulleys, air bearing and linear motor technologies.

Invetech provides full-spectrum product realization services, partnering with companies around the globe to create breakthrough products and custom automation systems. The experience acquired through more than 30 years in product design, development and contract manufacturing spans a range of healthcare market sectors including laboratory diagnostics, Point of Care diagnostics, cell and advanced therapies, and life sciences. For more information, visit invetechgroup.com.

Filed Under: Ballscrews • leadscrews, Linear Motion Tips

Tell Us What You Think!