The United States Air Force (USAF) is pursuing the development of a miniature drones that can transform from flying aircraft into underwater vehicles.

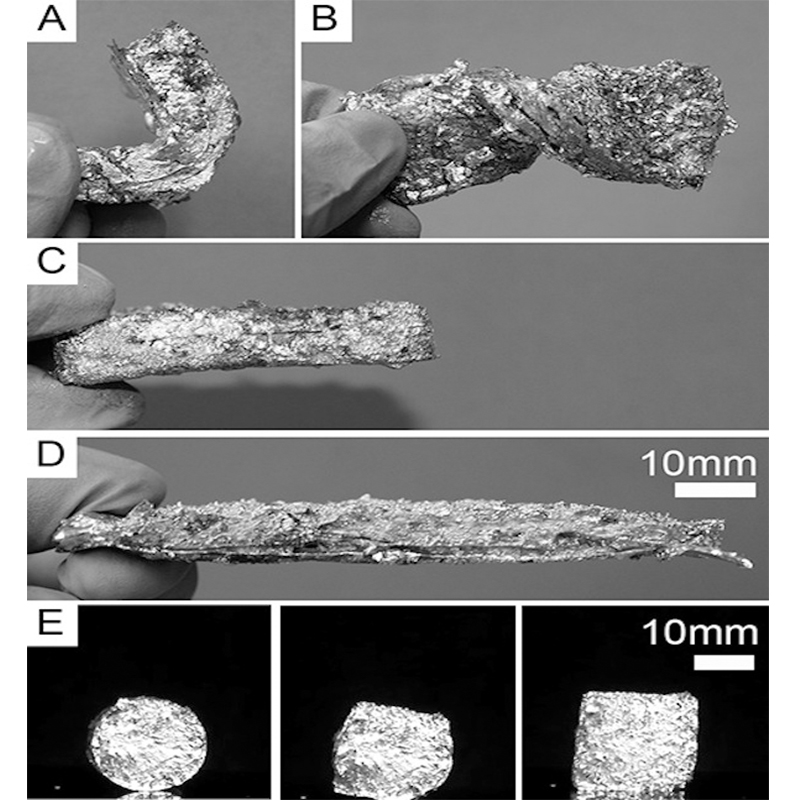

A step in that direction, Cornell University researchers have created a new composite material consisting of both silicone and metal, resulting in a kind of “morphing” material that the USAF wants to integrate into the wings of small aircraft.

At low temperatures, the metallic properties of the composite prevail, making it rigid and strong.

But when heated to 144 degrees Fahrenheit, the composite melts, causing the resulting foam to become soft and elastic. At this point, the composite can be molded into new shapes that will hold (without any loss in strength) once it cools back down.

(Credit: Rob Shepherd group)

“[The drone] can fly through the air, then shorten its wings and dive into the water. Without this ability its wings would break,” Ilse Van Meerbeek, a Cornell graduate student, told Live Science.

Researchers created the composite (with USAF funding) by dipping the silicone foam into the molten metal and then placing it into a vacuum, which filled the foam’s pores with the metal as the air was removed.

In addition to shape-shifting, the composite can self-heal; if two pieces are heated next to each other, the metals will melt and fuse together with only a slight loss in mechanical strength.

Filed Under: M2M (machine to machine)