Dorner is offering two cleaning modules for both dry and wet applications on its popular selling FlexMove system that allows continuous cleaning while the conveyors are operating.

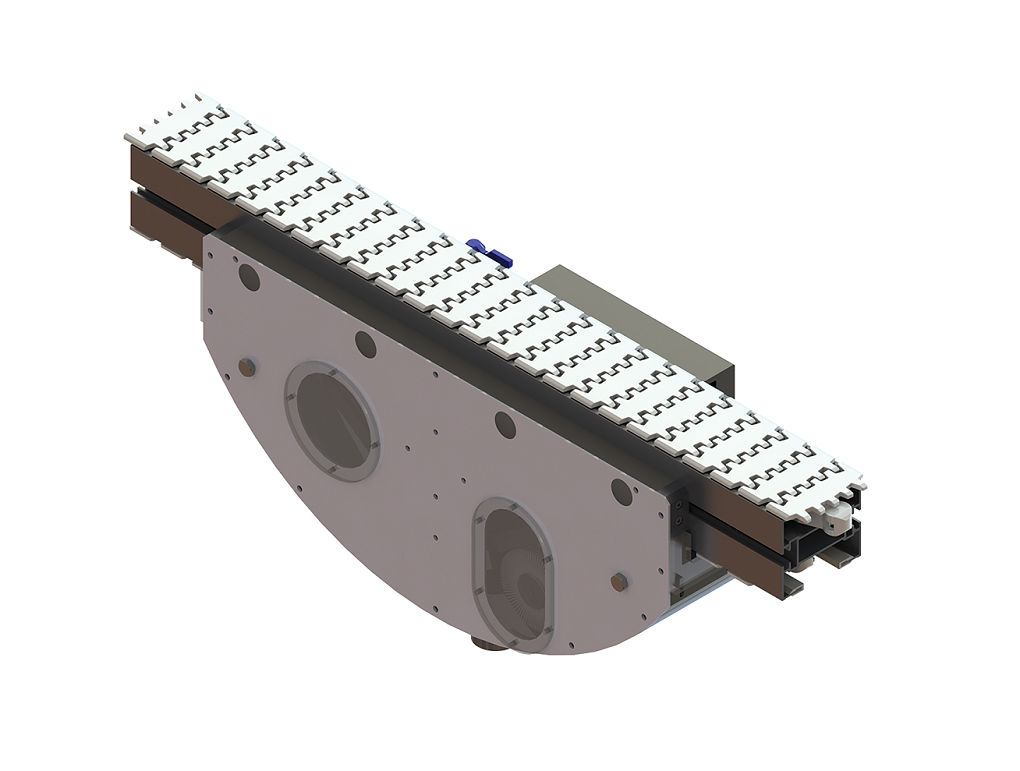

Designed for FlexMove conveyors, the Dry Cleaning Module provides continuous cleaning of conveyor chain for applications involving powder, dust and other dry contaminates, whereas the Wet Cleaning Module, which are designed for FlexMove stainless steel conveyors, provides uninterrupted cleaning of conveyor chain for applications with liquid, product overfill or package breakage.

Both modules operate by blowing air (for dry) or water (for wet) onto the conveyor belt through a closed housing system located on the frame underneath the conveyor. Both are designed to run continuously during operation, which provides longer, cleaner production runs with less overall maintenance. Additionally, both modules are completely mechanical, and do not require electrical components, programming or secondary motors.

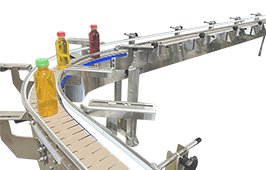

The FlexMove flexible chain conveyor brings the best engineering and performance standards in flexible conveying automation. These aluminum-frame, flexible chain conveyors are ideal when floor space is limited as they are designed to make tight 360° turns in and around machinery and equipment. FlexMove conveyors are ideal for packaging, part handling, product transfers, assembly automation, machine conveyance and tight spaces.

Features and benefits of the Dry Cleaning Module include:

· Slave-driven rotary brush scrubs chain surface; compressed air blows off particles, and vacuum extracts dust.

· Clean design with minimal area for dirt and debris to accumulate

· Available on FlexMove aluminum conveyors, FS (65 mm); FM (85 mm); FC (150 mm)

· Size requirement: 700 mm (L) x 300 mm (H)

· Minimum top of chain height: 250 mm (13.8 inches)

· Maximum conveyor length: 4.5 m (14.8 feet)

· Maximum conveyor speed: 50 m/min (164 feet per minute)

Features and benefits of the Wet Cleaning Module include:

· Slave-driven brush scrubs top and bottom surface of the chain

· Air knives blow off water from chain; vacuum draws away excess water

· Clean design with minimal area for dirt and debris to accumulate

· Available on FlexMove aluminum conveyors, SS (65 mm) and SM (85 mm)

· Size requirement: 700 mm (L) x 700 mm (H)

· Minimum top of chain height: 750 mm (29.5 inches)

· Maximum conveyor length: 4.5 m (14.8 feet)

· Maximum conveyor speed: 50 m/min (164 feet per minute)

Dorner

www.dornerconveyors.com

Filed Under: Conveyors