Three areas where you can look to cut costs on pneumatic cylinder applications include installation time, cables, and the sensors used for detecting the piston’s position. For example, first consider the sensor in a standard cylinder. Most standard cylinders use proximity switches, either internal or external to the aluminum housing that detect special targets or magnets mounted on the piston. Unfortunately, these proximity switches can be relatively expensive, take up valuable space, and are difficult and time-consuming to install.

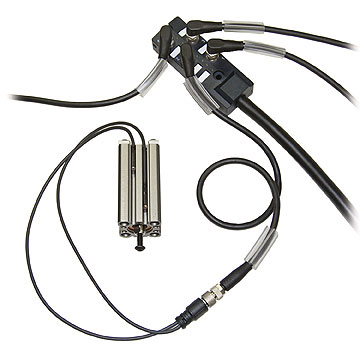

A dual-sensor, split-connector system coupled to a multiple-interface block (MIB) in a high-density application reduces the number of wires and potentially doubles the number of cylinder switches that can be used in the same installation.

A better solution is designed around a new dual sensor with a split connector. The configuration has two low-profile, magnetic-field sensors molded together into a single, four-pole connector. Compared to the standard application (where the end of the piston’s stroke is detected in both directions), the dual sensor system does the same job with one less connecting cable, fewer terminations, and less connective hardware, which require less time to install. This dual sensor arrangement can cut an application’s cost by 50%.

Even in a smaller application, a dual-sensor, split-connector system installed on a cylinder to detect the end of a piston’s stroke can reduce installation time and material costs compared to a standard two-proximity switch arrangement.

A dual-sensor, split-connector system combines two magnetic-field sensors with a single connector. This approach uses only one four-conductor cable and less installation hardware with fewer terminations than the standard method.

In another installation where numerous cylinder switches are densely packed, multiple interface blocks (MIBs) are typically used to reduce the number of wires needed to return to the control panel. However, you get a bonus when you use a dual sensor system in the same installation: It doubles the number of cylinder switches that can be connected to the same MIB, or it cuts the MIB size in half for the same number of switches. Either way, your cost-cutting goal is realized.

Balluff

www.balluff.com/vtwin

[email protected]

::Design World::

Filed Under: Pneumatic equipment + components, SENSORS, TEST & MEASUREMENT

Tell Us What You Think!