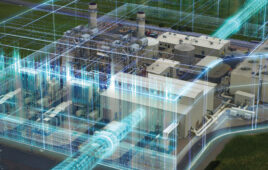

Following years of technical development and operational implementation design, Siemens introduces SIBERprotect for protection of critical infrastructure and OT systems at various industrial concerns, including power plants, water treatment facilities, all types of discrete manufacturing enterprises, military depots, data centers, and control stations. SIBERprotect brings the SOAR (Security, Orchestration, Automation, Response) concept to cyber-physical systems…

igus unveils AI-driven solutions for Industry 4.0 at Hannover Messe

In a groundbreaking showcase at Hannover Messe 2024, igus is set to redefine the future of sustainable industrial automation with its latest advancements in AI, smart maintenance, and low-cost robotics. With a focus on zero-lubrication and CO2-neutral solutions, igus introduces igusGO, an AI-powered app, alongside a series of smart sensor technologies designed to streamline maintenance…

Mitsubishi collaborates with Dispel to launch zero-trust remote access solution

Mitsubishi Electric Automation Inc. has closely collaborated with Dispel, a software provider for secure, remote connectivity in OT environments, to provide customers with solutions to grant on-site zero-trust network access from remote locations securely. Facilities can connect to the remote region through Dispel-enabled Mitsubishi Electric iQ-R Series WinCPU R102WCPU-W or the RD55UP12-V C Intelligent Function…

Streamlining automation with all-in-one control and visualization

By Linda Htay, IDEC Corporation When it comes to industrial automation applications, there has long been a degree of separation between “control” and “visualization” functions. Programmable logic controllers (PLCs) and human-machine interfaces (HMIs) have evolved technologically over decades to perform distinct but closely related operational roles. A closer look reveals why this has been the…

Hyson announces expanded Toolmind product line

Hyson, a business of Barnes Group Inc., and a maker of nitrogen gas systems for metal forming operations, announces the expansion of its Toolmind Secure Remote Monitoring System product line — empowering customers with more capabilities to enhance stamping operation control and efficiency. Hyson’s zero-scrap policy ensures that every production cycle counts and Toolmind plays…

Engineers emboldened by digital transformation community

Over the past year, I’ve spent a lot of time speaking with manufacturers about their digital transformation projects. They all have very different stories to tell because their application needs are distinct. But whether it’s a food manufacturer, a beverage producer, an automaker or a machine builder, they all have one thing in common: The…

Delta optimizes energy efficiency in GW-scale data centers for AI training at NVIDIA GTC

Delta, a provider of IoT-based smart green solutions, offered an in-depth presentation at NVIDIA GTC, a global AI conference, to highlight its new developments in power solutions from grid to chip to optimize energy efficiency in gigawatt-grade data centers for AI training. This includes Delta’s on-site displays of ORV3 racks, the 33 kW power shelf,…

Five things to know about leveraging wireless charging to support DX

Digital transformation (DX) initiatives continue to make headlines. The buzzword is synonymous with improving automation, safety, and efficiency in the manufacturing industry. More facilities than ever are integrating Industry 4.0 technologies such as sensors, IoT, and robots, into their operations to enhance modernization efforts, increase efficiency, and reduce downtime. Here, wireless charging of equipment found…

ABB opens refitted, state-of-the-art U.S. robotics facility

Refit will support customers and ABB’s leadership in growing US robotics segments, including Packaging & Logistics, Food & Beverage, Construction, Lifesciences & Healthcare, and Automotive electric vehicle production. New factory serves as US hub, developing and manufacturing AI-enabled technology to help businesses respond to labor shortages, global uncertainty, and the need to operate more sustainably.…

Hannover Messe: Altair’s multi-pronged approach

At the upcoming Hannover Messe in April, Altair will focus on a theme of “The Science of Possibility,” highlighting the company’s technologies for simulation, high performance computing (HPC), data analytics, and artificial intelligence (AI). Areas of interest will include: Simulation-driven design AI-powered engineering Digital twins, and AI on the factory floor We spoke to Mirko…

Design World launches the Digital Transformation Forum

Manufacturers are under pressure to take on a digital transformation that will add flexibility on the plant floor while increasing productivity. Key drivers of this technology step change include the need to reduce operating expenses and improve efficiency, all while facing a skills shortage and a lack of visibility across the supply chain. Recognizing this…

EXAIR’s new augmented reality web application helps improve customer experience

EXAIR provides customers with confidence when selecting the right product for their process. To continue facilitating a high-quality user experience, EXAIR.com has upgraded the resources available to users by adding Augmented Reality (AR) capabilities while visiting the site on a mobile device. Customers will now can not only view a 3D version of their selected…

Trends in artificial intelligence for 2024

According to Gartner’s research, up to 25% of organizations surveyed annually since 2019 said they plan to leverage artificial intelligence (AI) within the next 12 months. However, only up to 5% have deployed AI to production. Companies know that generative AI can dramatically improve operations, but inexperience and potential risks postpone the benefits. Predictive maintenance,…

Mitsubishi launches high-performance teach pendant for improved operability

Mitsubishi Electric Automation Inc.’s new R86T6 Teach Pendant evolved from the conventional, high-performance teach pendant to deliver customizable and intuitive functions to OEMs and end users. The R86TB is designed with a 10.1-in. high-definition display so that any function can be easily visible and accessed from the customizable HOME screen or page list. Functions of…

IDEC 7-in. combined PLC+HMI increases display size and I/O options

IDEC Corporation has expanded its SmartAXIS touch family with the new FT2J Series combined PLC+HMI. A compact all-in-one form factor combines built-in full-function controller features and functions, both onboard and expandable I/O, and an advanced technology 7” touchscreen display, providing many advantages for a wide variety of industries. Compact, simple, and streamlined An all-in-one PLC+HMI…

Hannover Messe focusing on AI’s impact for 2024 trade fair

This year’s Hannover Messe trade fair (said to be the world’s largest industrial trade show) takes place from April 22-26 in this northern German city, and some may say the outlook for manufacturing is uncertain. For sure, in his opening remarks, Dr. Jochen Köckler, Chairperson of the Managing Board, Deutsche Messe AG listed many reasons…

Seeing the future of AMR vision systems

Mobile robot technology is moving fast, and generative AI is pegged to transform AMR vision systems to enable more integrated solutions. Advanced machine learning and visual processing are major trends in automated mobile robot (AMR) development. According to Gartner’s Emerging Tech Impact Radar, advanced computer vision and AI acceleration will be among the most important…

Flying towards sustainability

According to Deloitte, “the demand for sustainability, product innovations, and wartime defense is expected to result in rapid technological evolution” in the aerospace and defense (A&D) industry”. Innovations like electric propulsion systems and more precise manufacturing will be crucial. Here, Chris Johnson, managing director at specialist bearing supplier SMB Bearings, explains why industrial bearings will […]

Pepperl+Fuchs VisuNet FLX HMI series now offers extended temperature range

Pepperl+Fuchs is expanding the VisuNet FLX HMI series with a new option, making it even more flexible. The series offers various HMI systems for a wide range of applications and installation requirements in ATEX/IECEx Zone 2/22, NEC 500 Div. 2, and non-Ex areas. The modular “one-size-fits-all” design allows for the precise HMI solution configuration and…

Feeding time: HMIs and PLCs help in grain blending application

By Ethan Taylor, Taylor Controls When a grain blending company realized it was time to upgrade its aging controls originally developed in-house, it looked for just the right combination of PLC and HMI automation to advance its capabilities. The grain production company batches and blends ingredients to produce various livestock feed. Over the years, the…

Siemens Digital Industries and Voltaiq optimize battery manufacturing

Siemens Digital Industries Software and Voltaiq combine their strengths to offer unparalleled capabilities for battery manufacturing-focused companies. This collaboration aims to bring together the production-proven capabilities of both Siemens’ Insights Hub and Voltaiq’s Enterprise Battery Intelligence (EBI), customers can gain access to unparalleled capability specific to battery-domain companies to help rapidly scale operations smoothly, from…

January 2024 Issue: 2024 Leadership in Engineering

Keeping a focus on engineering leadership Within each January issue of the magazine, we focus on the topic of leadership in engineering. And while that’s usually focused on the leadership qualities of manufacturers as well as individual engineers, I’m proud to announce here that our parent company, WTWH Media, continues to take a leadership role…

Carnot uses Creo and Windchill to decarbonize engine technology

Carnot, a London startup, has signed a new deal with PTC that will help it tackle the trillion-dollar challenge of decarbonizing industry, long-haul transport, and off-grid power. The company was formed by Archie Watts-Farmer, Francis Lempp, and Nadiur Rahman in 2019 and will extend its use of the digital transformation specialist’s CAD design software Creo […]

ABB Robotics partners with XtalPi to build intelligent automated laboratories

ABB Robotics and XtalPi have entered a strategic partnership to produce a range of automated laboratory workstations in China. The new, automated laboratories will boost the productivity of R&D processes in biopharmaceuticals, chemical engineering and chemistry, and new energy materials. “Our collaboration with XtalPi marks another milestone for ABB’s collaborative robots in the life sciences…

Brightpick explains machine vision and AI in intelligent warehouse automation

Brightpick unveiled new details about the proprietary world-class machine vision and AI that are critical for the seamless operation of its Brightpick Autopicker robots. The technologies are used for everything from scanning totes (bins) to create 3D models for future picking of items, to determining ideal picking angles for both totes and individual items. The…