Easylock™ shaft collars from Amacoil/Uhing install quickly without special tools to provide non-slip holding of tools and reels on smooth, case hardened (Rockwell > 55) shafts. A new option – Easylock positive release – assures the collars won’t become jammed on shafts.

A clamping control wheel on Easylock allows users to adjust the holding force from 90 to 1,124 pounds. As the Easylock clamping control wheel is turned clockwise, the clamping unit is forced against the object being secured which holds it in place. This can generate compression forces which push back against the Easylock, sometimes interfering with the quick-release mechanism then making it difficult to slide the Easylock collar off the shaft.

Previously, in order to keep this from happening, it was necessary to advance the clamping control wheel a few turns before sliding the Easylock onto the shaft. The new positive release feature eliminates this step. Positive release is activated when the clamping control wheel is turned all the way in a counterclockwise direction. When the wheel is backed off in this manner, it contacts a stop pin which automatically releases the locking mechanism so that the quick-release functions as it should.

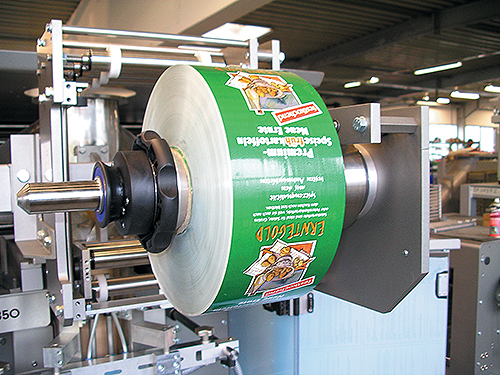

Easylock shaft collars with positive release are designed to reduce downtime to help maintain consistent production rates. The quick-release feature makes Easylock collars well suited to high volume production where frequent changeovers of shaft-mounted tools, reels/spools and other objects are required. The positive release feature is standard on Easylock sizes 25, 30, 35 and 40, and will soon be included on the smaller sizes 10, 12, 15, 16, 20 and 22.

If Easylock is used to hold spools in level winding operations, Easylock pintle points are attached to the face of the unit. As holding force is increased, the points are forced into the spool bore creating a non-slip interface between the shaft and the spool. This permits rapid starts and stops without rotational play of the spool on the shaft. The pintle points also make Easylock useful in processes such as high-speed roll-fed lamination and stretch-wrapping. Easylock is also effective in static procedures such as holding down mounting plates and machine covers. Easylock collars are maintenance-free.

Amacoil, Inc.

www.amacoil.com

Filed Under: Collars • locking devices

Tell Us What You Think!