Dorner’s new Edge Roller Technology (ERT 250) conveyor has received certification for use in ISO Standard 14644-1 Class 4 rated cleanrooms. This means Dorner’s ERT250 will conform and not contribute to the contamination of cleanrooms to those standards.

Dorner’s new Edge Roller Technology (ERT 250) conveyor has received certification for use in ISO Standard 14644-1 Class 4 rated cleanrooms. This means Dorner’s ERT250 will conform and not contribute to the contamination of cleanrooms to those standards.

Cleanrooms and other controlled environments provide management of airborne particulate contamination to appropriate levels for accomplishing contamination-sensitive activities. Industries that regularly use cleanrooms in their manufacturing processes include pharmaceuticals, medical device, healthcare, assembly and packaging.

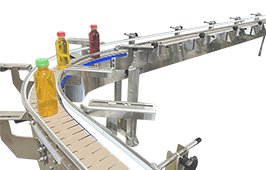

The ERT250 is suitable to operate in cleanroom environments requiring a pallet handling conveyor capable of zoning for accumulation and automation assembly applications. The ERT250 nicely complements cleanroom applications as it uses rollers, not belts which can result in releasing dust into the air, to move pallets smoothly with no friction. The rollers are driven by a patent-pending, energy efficient linear gearbox that gives customers added flexibility with motor positioning and zoning. This allows for zone and slip roller operation which doesn’t release dirty particulates into the air like pneumatically-operated conveyor systems.

The conveyor’s open-center design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT250 is ideal for applications calling for pallet or tray handling; no- and low-back pressure accumulation; and medium to heavy load assembly automation.

The non-contact zone control provides simplified traffic control that eliminates pallet stops and costly pneumatic valves. Conversely, slip rollers can be used for full length runs with conventional pneumatic pallet stops. The rollers are easily accessible and can be replaced quickly without affecting the remaining portion of the conveyor.

Technical specifications of the new ERT250 include:

• Widths 120 mm to 960 mm wide

• 38 mm diameter rollers on 50 mm centers

• Loads up to 250 lb per pallet or tray

• Loads up to 15 lb per roller

• 150 mm minimum long tray

• Speeds up to 30 m (100 ft) per minute

• Aluminum frame with two T-slots

• Energy efficient brushless DC gearmotors and controllers; motor controllers use Ethernet IP for easy communication

• Reversible

Automation modules:

• Navigate 90° and 180° corners

• Lift and transfer

• Lift and locate

• 90° pusher

Three transportation modes:

• Non-contact accumulation

• No- or low-back pressure slip roller accumulation

• General transport

Dorner Manufacturing

www.dornerconveyors.com

Filed Under: Conveyors