← PREVIOUS PAGE || Rapid adoption of AGVs means a larger array of application requirements and a demand for faster design cycles. Here, integrated motors provide modularity that lets designers iterate designs quickly, and high-torque-density motor designs let smaller motors deliver the necessary torque, Rice added.

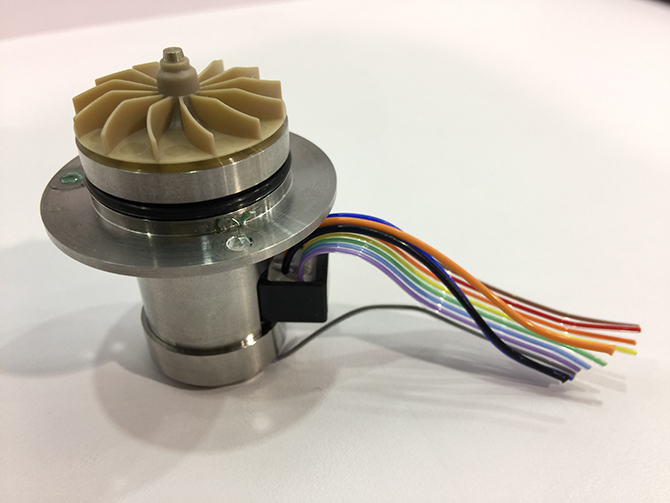

A Motion System Selector online purchasing portal from MICROMO of Faulhaber lets design engineers quickly find, configure, and purchase motors. Otherwise, engineers can work with the manufacturer to source integrated assemblies (as the pre-engineered solution shown here).

Still others cite the importance of motor power density in these kinds of mobile applications — and how one design never fits all. “With this in mind, we developed Ultra EC brushless dc motors with a patented U-shaped coil that maximizes power density,” said Beckstoffer. The coil lets design engineers pick from multiple options depending on whether an application requires high speed, high torque, or a combination of the two.

“Having more power available from the motor lets engineers reduce the overall size of end product … and flexibility in motor lengths and base options ultimately let design engineers develop smaller products while boosting value to end users,” added Beckstoffer of Portescap.

The DRS2 Series compact linear actuator from Oriental Motor is a precision ballscrew actuator fitted with an AZ Series stepper motor and absolute mechanical encoder. This is one example of the industry trend towards increasingly integrated stepper-motor designs.

Of course, mobile motion designs such as AGVs are only one of many technologies that make automated warehouses work. “What we see in logistics and distribution centers is a continuing trend of making systems smarter. This means replacing older less-intelligent actuators such as pneumatic actuators with higher precision and programmable electromechanical actuators that can hold multiple positions over the full stroke,” said Rice.

According to Rice, integrated motors (such as integrated step and servo motors) play a key role in this trend. “That’s because logistics systems are typically spread over a large physical area … and eliminating control cabinets to house drive electronics can significantly lower the cost of upgrading to integrated motors,” he noted.

Design miniaturization (and what that requires from motors)

Recent years have brought significant advancements in the construction of servomotors. “The physics of optimizing the magnetic flux generated from rare-earth magnet assemblies (and new production techniques) have leveraged improvements in motor designs. So, we’re seeing continued improvement in the torque density of servomotors well beyond what I once believed achievable,” said Osak of Electromate.

“In layman’s terms, the torque output one could get out of a NEMA-34-frame servomotor from eight or 10 years ago is now achievable with a NEMA-23-frame servomotor. In the same way, torque output of a NEMA 23 frame servomotor from eight to 10 years ago is now what today’s NEMA-17-frame motors can produce.” Some electric motors have far higher power density than in the past — with 50 to 100% more torque capacity than comparably sized motors from just a decade ago.

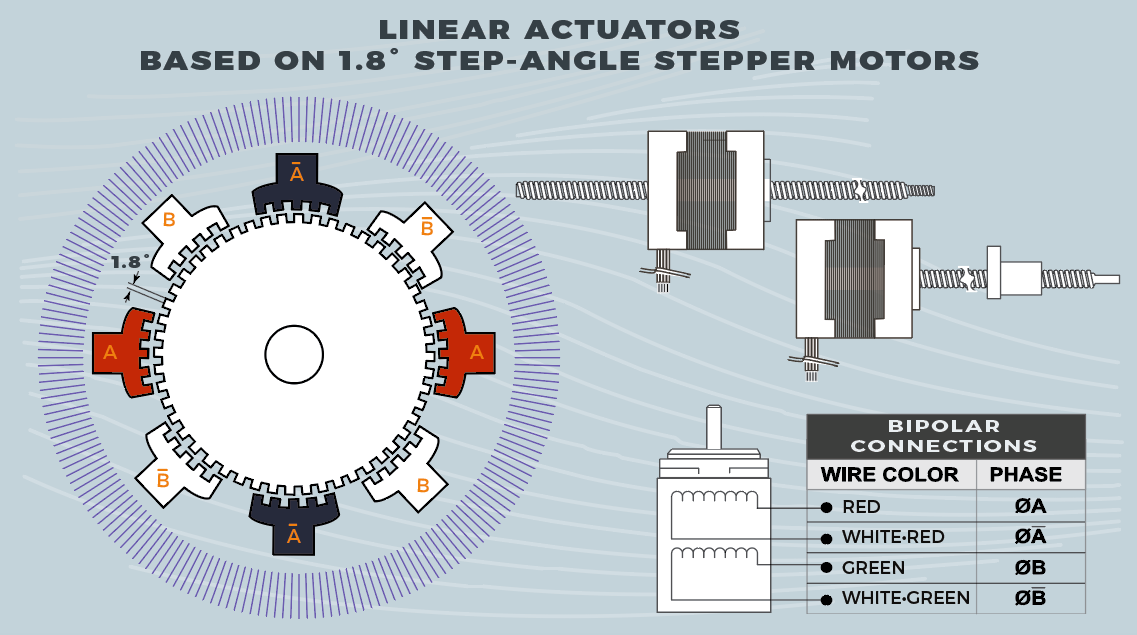

Basic stepper motors have yielded to highly integrated designs, including those for linear motion … such as linear actuators from Schneider Electric Motion in NEMA sizes 14, 17, and 23. Based on single-stack 1.8° stepper motors with leadscrews, sometimes the manufacturer also integrates the actuators with programmable motion controllers, drive electronics, and optional encoders to form MDrive Plus actuators.

Case in point: An engineering team at ISL Products Intl. Ltd. recently reduced current draw of an existing motor by 40% … in addition to helping an OEM reduce EMI and RF interference, to let a motor function in a region of the end product sensitive to such influences. (On a related note, the team has also designed miniature gearmotors with operating life that’s twenty times than that of standard gearmotors, according to Ken Kawaller, president of ISL.)

“Miniaturization is going to continue, because miniaturization imparts better use of space, reductions in mass, and reductions in cost — so I don’t see a point of diminishing return,” said Osak. “Of course, there will be a point at which we get diminishing returns — where gains in servomotor construction simply don’t boost torque output appreciably — but we haven’t gotten there yet.”

Besides motor construction, tighter integration of controls, connection hardware, and linear-motion PT components also help keep motor-driven designs compact. “Integrated motors continue to drive simplicity and turnkey operation for our customers. This year we’re launching our first integrated motor linear actuator,” said Rice. “The product integrates a motor, encoder, controller, screw (ball or lead), and nut into a single linear actuator assembly” — and the result is a miniature linear actuator with closed-loop positioning capabilities right out of the box.

Complete motor-powered assemblies

Efforts by motor and motion-component makers have grown to simplify integration for OEM engineers. maxon has offered value-added services in the U.S. for a while — for example, by offering flying leads or pre-attached connectors of OEM choosing. Another example is custom mounting plates, which the motor supplier machines in the U.S. These modes of customization are typically on orders with small or medium quantities. But now such efforts are expanding.

Here’s another example of the trend towards integrated stepper systems: LinFinity actuators from Lin Engineering include a nut, polished leadscrew, and stepper motor. A reservoir in the nut distributes a consistent layer of grease during operation.

Massachusetts has been maxon precision motors’ home for decades, but the company is currently relocating to a facility in Taunton, Mass. to double facility size and capacity — and do move value-added and engineering work — even to quoting and completing subassembly builds that (until now) have been done mostly at the manufacturer’s Switzerland headquarters. “We’re currently hiring engineers in the U.S. capable of design, drawing, and layout work to expand local services. The aim is to import higher volumes of base product from overseas and then execute the customization stateside,” added McGrath … NEXT PAGE →

Filed Under: Drives (stepper) + amplifiers, Gears • gearheads • speed reducers, Motors (direct-drive) + frameless motors, Motors • stepper, Motion Control Tips

Tell Us What You Think!