Modern electronic diesel engines use ultra-low sulphur fuel and have sophisticated fuel management systems that include integrated throttle control. Use of these engines results in machines with greater efficiency, enhanced functionality, increased operator safety and reduced carbon emissions. In regions where emissions are highly regulated, they offer a solution to meet the equivalent of Tier 4F (Stage 4) emissions level. However, these benefits come at a cost and electronic engines may not be competitively viable in certain applications or geographical regions.

Traditional mechanical diesel engines cost much less than their modern electronic counterparts and it is expected they will continue to be used for some time to come; in particular where emissions regulations are not as stringent or ultra-low sulphur fuel is not readily available. The use of electric throttle actuators on these engines increases efficiency, functionality, emissions rating and safety. Such actuators can control a mechanical engine smaller than 24.8 hp, which achieves the equivalent of Tier 4F (Stage 4) emissions level, as well as larger engines in regions that allow Tier 3 emissions level.

In mobile off-highway applications, a mechanical throttle cable connected to the driver’s cab has traditionally controlled the throttle on a drive or auxiliary engine. These cables have a large bend radius, which presents design challenges in running cables, particularly to auxiliary engines that are frequently located far from the cab. These size and space restrictions can lead to compromises in ergonomic design, making equipment more difficult to operate. Mechanical engines also require periodic lubrication that is difficult to complete and often overlooked, which may lead to issues with performance.

Off-highway vehicles use diesel or gasoline engines to drive the vehicle and to provide a power take-off to operate equipment. The drive engine is often used to power a hydraulic pump that drives a cylinder to perform work such as moving a boom and bucket on an excavator. Auxiliary engines can be difficult to control as equipment functions can require they be operated at different speeds for different tasks. When manually controlled, the risk of operator error can impact efficiency and increase the potential of damage to machinery.

Electronic throttle controls allow for greater machine efficiency by adjusting engine rpm based on whether it’s working or idle.

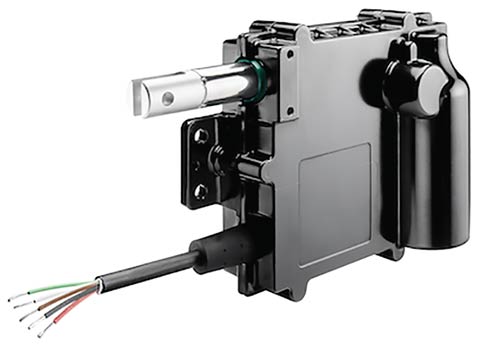

Installed in close proximity, or directly to the throttle linkage and requiring just an electrical cable or communications bus to the cab, electric throttle actuators can be controlled by a simple potentiometer, with or without limit switches, and can be positioned for optimal machine design as no direct access is required for operator interface.

Electric throttle actuators can also be interfaced with a control system that can adjust the speed of the motor to a pre-determined set point based on the work being performed. Pre-setting rpm levels can improve the performance and fuel economy of a machine while reducing noise and emissions. For example, if a crane operator is manually controlling the throttle, the operator is likely to keep the engine at the speed required to operate the crane even when the crane is not being operated for a short period of time. The control system can drop the engine speed to idle when the joystick is not moved for a defined time interval and, when the operator touches the joystick, automatically increase the throttle to the pre-defined operating engine rpm.

With a traditional approach, an electronic control unit (ECU) is required for each actuator. By using smart actuators that use a communications bus, only a single cable needs to run from the controller to all actuators. Each actuator has a unique address, listens to every signal from the vehicle control system and responds only to signals regarding the engine throttle system. These smart actuators also provide status information, alerting the control unit of its speed and position and enabling a greater level of automation. The implementation of a bus system in a vehicle makes it simple to add additional sensors that can include other measurements, such as temperature or load.

Electric throttle actuators also provide the opportunity to integrate throttle control with other vehicle functions. Take the example of an engine that must be operated at a speed of 2,000 rpm to power a hydraulic pump for a specific vehicle function. The control system simply sends out a command to the actuator to increase the speed of the engine. The system then watches the response from the tachometer and turns off the actuator when the engine has reached 2,000 rpm. It can then automatically turn on the equipment required to perform the specific function.

Modern throttle actuators are designed to withstand under hood temperatures (with operating range from -40 to 125° C), vibration and moisture and provide the high cycle life required for demanding off-highway applications. New models can withstand water, dust and dirt and usually meet IP67 or IP69K standards—making them suitable for high pressure, high-temperature washdown. A typical model is designed for 500,000 cycles and can operate on a 50% duty cycle at maximum dynamic load. The actuators are also designed and tested to withstand the shock and vibration levels typically seen in the off-highway environment.

The use of electric throttle actuators and sensors that measure demand has been shown to reduce fuel consumption, noise levels, and engine wear and tear by optimizing engine rpm on portable jobsite equipment such as generators and air compressors. An engine driven generator for charging batteries on a mobile communication or lighting system, for example, uses a sensor to control engine rpm in line with the charging requirement of the batteries. In applications such as man lifts, where generators are used to provide working voltage to portable power tools, such as welders, grinders and drills, controlling the speed of the engine is critical to providing appropriate voltage levels.

In applications such as irrigation and fire fighting, the ease of remote operation of electronic throttle controls enables the operator to adjust flow from a remote position, which is particularly useful because pumps provide output directly proportional to the rpm of the engine.

Thomson Linear

thomsonlinear.com

Filed Under: Actuators, MOTION CONTROL

Tell Us What You Think!