Exlar announces the newest EtherNet-based communications protocol supported by the company’s robust Tritex II™ linear and rotary actuators—Modbus TCP/IP. To maintain standard connectivity, the EtherNet connection is offered through an M12 connector.

The Modbus TCP protocol pairs the robust Modbus RTU protocol already supported by the Tritex product line with the convenience of EtherNet connectivity. In addition to Modbus TCP support, Exlar Expert™ software now includes enhanced functionality for customers using Modbus commands through an HMI or PLC. Rather than searching through manuals for individual parameter addresses while programming the PLC, a Modbus Mapping table allows users to map all parameters they wish to use in a contiguous register bank composed of up to 100 registers. This will allow a PLC program to perform a single read operation and a single write operation to all selected registers, rather than reading and writing one register at a time or being forced to read in blocks of data that may not all be used.

Tritex II actuators operate from 100-240VAC, allowing direct connection to factory power sources. Enhanced software features include 16 programmable indexes, linked moves and firmware flash upgrade capability via the actuator’s Modbus port. This port—through the RS/485 protocol—allows complete control, programming and monitoring of all aspects of the Tritex II actuator as it performs an application. Other communications options including the following: Ethernet IP, HART, CAN Open and CAN J1939 protocols.

With eight digital inputs, four digital outputs, plus one analog input and output, the Tritex II actuator has ample I/O capability. Feedback choices include analog hall effect (standard) and an incremental encoder for high positioning resolution. The new Tritex II design offers excellent connectivity with internal terminals accessible through the actuator’s removable cover. Tritex II also offers provision for imperial or metric threaded ports for cable sealing glands, optional M23/M16 connectors for power and I/O, and an M8 connector for the RS485 port.

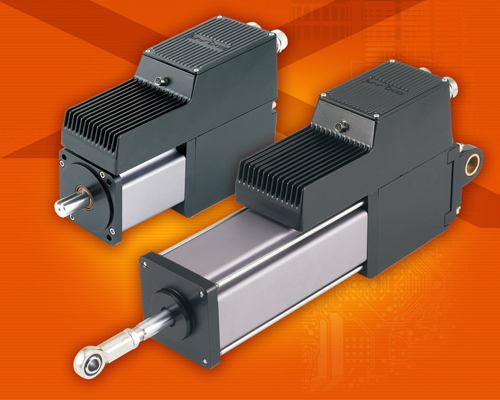

Tritex II linear actuators provide the same form factor as hydraulic and pneumatic actuators, and allow simple and clean all-electric retrofits for former fluid power applications. They are available with many different mountings (metric or imperial), such as front flange, rear clevis mount, side mount, trunnion mount, extended tie rod, and rear flange.

Features of the Tritex II linear series that makes it particularly effective and easy to use include:

* 90 and 115 mm frame sizes

* 3 to 24-inch strokes available (75 to 610 mm)

* 0.1, 0.2, 0.5, 0.75-inch lead roller screws (2.54, 5.08, 12.7, 19.05 mm)

* Standard or high mechanical capacity roller screw drive

* Peak force to 7370 lbf (32.8 kN)

* 25 inches per second max linear velocity (635 mm/s)

* 100 to 240VAC power

* Multiple standard and custom mounts available

* Analog hall or incremental encoder feedback

* Multiple connectorization options

* IP54 sealing standard; IP65 sealing optional

* RS485 serial communications for monitoring and control via Modbus

* Molded and shielded cables available

* Option boards for other I/O types, I/O expansion, various network types, etc.

Tritex II rotary actuators are available in standard IEC metric dimensions. Direct drive units as well as units with integral planetary gearing provide compact powerful solutions for most rotary applications. Custom mounting and options for both rotary and linear actuators are available to meet all of your installation requirements.

Features of the Tritex II rotary product that makes it particularly effective and easy to use include:

* 90 and 115 mm frame sizes

* Motor torques to 95 lbf-inch continuous and 205 lbf-inch peak (10.7 Nm and 23.2 Nm)

* 100 to 240VAC power

* Integrated planetary gearing option 4:1 to 100:1 ratios offering torque output to 4696 lbf-in (530.4 Nm)

* Up to 1700 rpm base motor speed* Multiple standard and custom mounts available

* Analog hall or incremental encoder feedback

* Multiple connectorization options

* IP65 sealing standard

* RS485 serial communications for monitoring and control

* Molded and shielded cables available

* Option boards for other I/O types, I/O expansion, various network types, etc.

Exlar Corporation

www.exlar.com

::Design World::

Filed Under: Factory automation, Actuators, Connectors (electrical) • crimp technologies, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!