Electrical components need to be protected in a wide range of applications.

Whether they are in automotive or industrial electronics, it’s crucial that chips and PCBs are shielded from mechanical stress and harsh chemicals.

Examples of an application with vulnerable parts are exhaust sensors used in engine control, or the components used in hot gear oil.

Casting compounds are a great alternative to injection moldings to protect these components, because injection molds can make assemblies more complex and expensive. Adhesives offer more versatility in the manufacturing process.

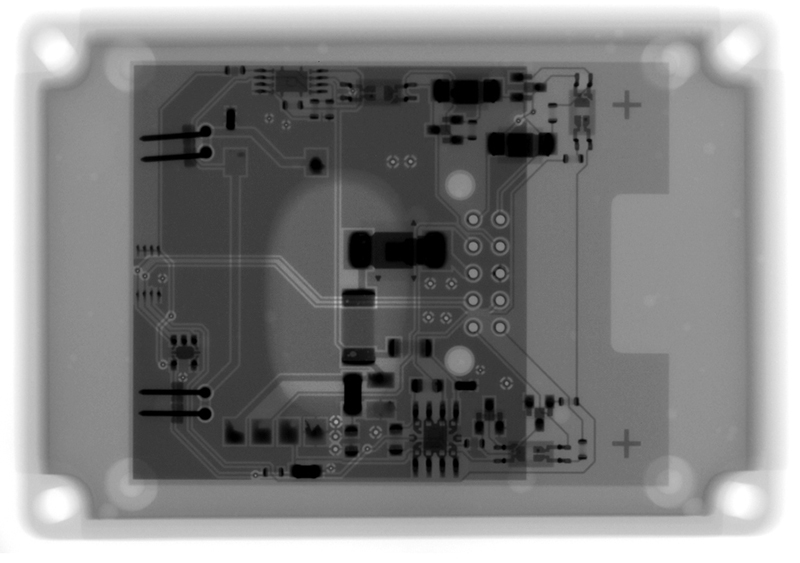

X-ray of casted PCB with air bubble. Image credit: DELO

Although adhesives can be bond parts together quicker and can be a more cost-effective solution, they do need to be dispensed carefully.

Air bubbles can become trapped in undercuts and narrow clearances. The air in these parts can expand and contract easily when heat is applied, leading to tensions and cracks through which chemicals, like oil, can attack the component.

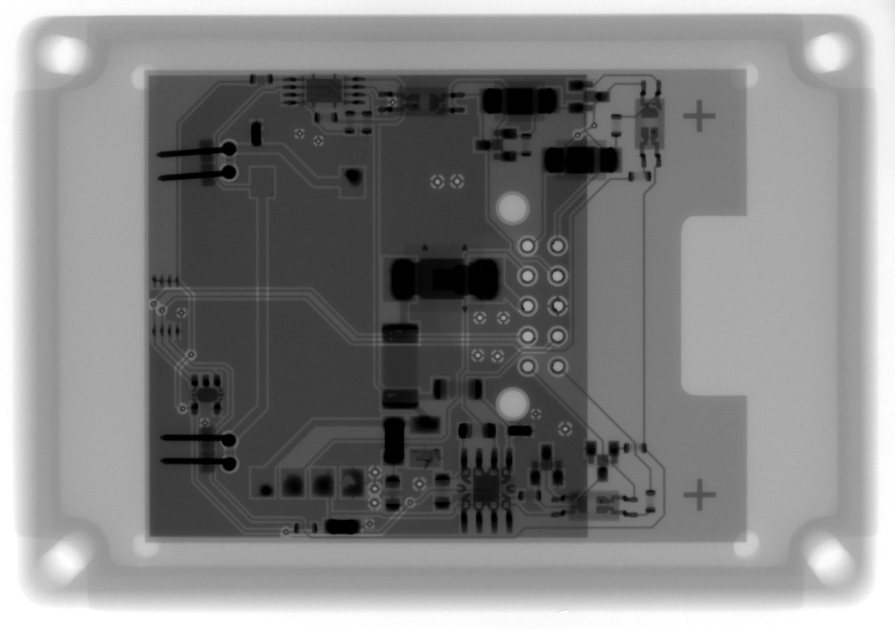

Vacuum casting is a solution for applications that have complex geometries, as well as high performance and security requirements.

The vacuum prevents the spread of bubbles while dispensing the adhesive and allows it to flow through components and reach crevices that would normally be unreachable.

X-ray of casted PCB without trapped air. Image credit: DELO

Air pressure is reduced in the vacuum casting chamber, as low as one millibar. This “quasi vacuum” is the optimum pressure level, since lowering it any further would consume too much energy, last longer and may damage the parts being worked on.

For example, a condensator can burst when low outer pressure puts stress on the parts encapsulated air. Therefore, vacuum levels should be carefully considered in accordance with the parts in an application.

While some companies may think this technique is too expensive or may not have tested using this method at all, many companies have begun implementing this technique recently.

Affordable solutions for R&D and small production volumes have been developed over the last few years. From a lab testing standpoint, the reliability gained from vacuum casting far outweighs the monetary cost of the technology.

Filed Under: Materials • advanced