If you manage or design safety-related equipment for nuclear power plants, your solenoid valves may be approaching their qualified life limit. Qualified life is primarily driven by material degradation caused by radiation, thermal and environmental exposures. One way to obtain a longer qualified life is to select solenoid valves with a new and improved thermal design for better heat dissipation. This design, which incorporates the coil into an epoxy-encapsulated solenoid assembly, not only lengthens the valve’s thermal life but also improves the solenoid’s electromagnetic properties—delivering the same maximum operating pressures at a lower coil wattage in most applications.

Improving traditional valve designs

A coil’s worst enemy is heat. Specifically, prolonged periods of time at excessive temperatures can cause the coil’s insulation to degrade. In general, heat can come from a variety of sources, including high-temperature fluids passing through the valve, the coil’s electrical energy or simply the air surrounding the coil. The resulting internal temperature is what determines the coil’s required insulation class: Class B (130°C), Class F (155°C) or Class H (180°C). Exceeding these ratings can cause the coil to open or burn out prematurely.

A coil’s worst enemy is heat. Specifically, prolonged periods of time at excessive temperatures can cause the coil’s insulation to degrade. In general, heat can come from a variety of sources, including high-temperature fluids passing through the valve, the coil’s electrical energy or simply the air surrounding the coil. The resulting internal temperature is what determines the coil’s required insulation class: Class B (130°C), Class F (155°C) or Class H (180°C). Exceeding these ratings can cause the coil to open or burn out prematurely.

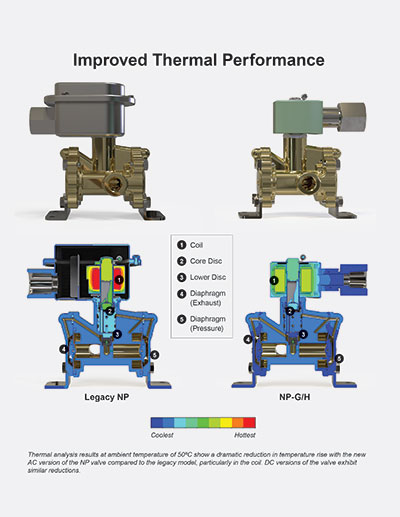

Traditional solenoid valves house the coil in a metallic enclosure. This design, however, causes the air surrounding the coil to act as an insulator, preventing the heat from dissipating and raising the valve’s internal temperature. This type of enclosure ages your valve, reducing its qualified life.

Better heat dissipation, longer qualified life

Alternatives to the traditional solenoid valve design can overcome these thermal shortcomings. Emerson’s Nuclear Qualified (NP-G/H) 2-, 3- and 4-way solenoid valves integrate its RedHat II technology, which includes a one-piece, epoxy-encapsulated solenoid coil that improves valve performance and extends the component’s lifecycle. The epoxy encapsulation serves as the enclosure with the magnetic frame molded into the coil. Thanks to this design, the coils and solenoids reduce thermal degradation by dissipating heat more effectively than traditional coils.

In addition to reducing heat degradation, the RedHat II solenoid design provides a number of other benefits, including:

In addition to reducing heat degradation, the RedHat II solenoid design provides a number of other benefits, including:

- Longer qualified life. Depending on the environmental conditions, typical NP series solenoid valves have a qualified life of 3 to 4 years. Thanks to their lower operating temperature, NP-G/H solenoid valves have a much longer qualified life — up to 8 to 12 years.

- Qualification report bridging. Designed as an upgraded drop-in replacement, NP- G/H solenoid valves facilitate the plant’s EQ acceptance criteria — minimizing required documentation.

- Ease of coil replacement. Whereas other solenoid valves require substantial disassembly, NP-G/H valves involve simply removing a high-shock clip and disconnecting the conduit to replace the coil. New quick disconnect (QDC) electrical connection options are also available, making it quick and easy to replace existing coils and valves while reducing the time spent in dangerous or containment areas.

Common applications

With their wide range of sizes, construction materials and pressures, NP-G/H direct-acting and pilot valves can suit the needs of a variety of nuclear applications, including:

- Pilot operators for control valves

- Pressurizing and venting cylinders

- Selection and diversion of instrument air

Additionally, these valves have the same fluid piping configuration, mounting brackets, EPDM and FKM elastomers, pressure rating and flow rating as NP legacy valves.

Robust valve construction and testing

Not only do NP-G/H series solenoid valves dissipate heat more effectively than traditional valves, but

they are also ruggedly constructed for use in nuclear-specific applications. They can operate from 0 psi to the valve’s maximum-rated pressure. Most nuclear applications fall in the 80–115 psi range, but many NP-G/H valves can work over 115 psi and below 5 psi if necessary. To make replacing current nuclear valves easier, the NP-G/H series retains the same brass or stainless-steel bodies and elastomeric and pressure vessel components as previous NP models. Many materials, including the elastomers, are designed to meet the harsh degradation effects found in nuclear applications. For example, EPDM rubber withstands high radiation levels, while Viton withstands lower radiation levels but higher temperatures.

These valves are also 100% inspected and functionally tested prior to shipment to ensure they meet the rigorous demands and high expectations of the nuclear industry. For example:

- Valves are designed and manufactured to comply with strict industry requirements — 10 CFR 50 — Appendix B and Qualification Report AQR 100368.

- Solenoid enclosures can withstand Loss-of- Coolant-Accident (LOCA) and High Energy Line Break (HELB) environments, as well as seismic loading for Safe Shutdown Events (SSE).

- Valves meet or exceed IEEE specifications (IEEE-323, IEEE-344 and IEEE-382).

- Local engineering teams provide ongoing customer support.

ASCO

www.emerson.com/ASCO

Filed Under: Flanges • supports • mounts • brackets, Valves, MOTION CONTROL, MORE INDUSTRIES, Solenoids