“Environment” is a difficult parameter to quantify when selecting recirculating linear bearings or ball screws. Unlike load, stroke, or speed, there are no programs or calculations that help you choose the right bearing based on environmental factors. But environmental conditions can have a big impact on the performance of linear bearings and ball screws. Because these components operate with metal-on-metal contact and tight tolerances, there’s little forgiveness for contamination, but that doesn’t mean recirculating bearing guides and ball screws can’t be used in harsh environments. In fact, these are sometimes the only components that can meet the performance requirements and withstand the environmental challenges posed by the application. For these situations, here are some tips on how to deal with various environmental conditions that can be detrimental to recirculating guides and ball screws.

Environmental challenge: Liquid contamination

Liquid contamination poses two problems to linear bearings and drives—not only does it attack the bearing material and promote rust, in large quantities or at high pressure, it can wash lubrication out of the bearing. Liquid hazards can range from simple water splash, to washdown with caustic cleaning solutions, to spills of acidic beverages (think juice or soda). This is why it’s important to understand the exact makeup of the liquid contamination and the amount of exposure (splash, high-pressure spray, or possible submersion).

Food and beverage applications often require washdown with corrosive chemicals.

Corrosion is a result of chemical attack on the metal surfaces by hostile fluids or environmental contaminants.

Image credit: The Barden Corporation

One of the best solutions for liquid contamination is to mount the bearing or screw assembly (or linear actuator) in an orientation that minimizes the liquid’s ability to get to the bearing surfaces, and that allows it to run off if it does. Full-contact seals and proper lubrication will also help prevent rust from developing on the raceways of steel components. And aluminum or stainless steel should be used wherever possible—for example, a linear actuator with an aluminum housing and stainless steel hardware. If none of these options is feasible, or if the contamination is unavoidable or highly aggressive, there are many platings and coatings that can be applied to steel or aluminum to help these materials withstand a wide range of liquid contaminants.

Solutions

• Use full-contact seals on linear guides and ball screws

• Orient the system to minimize the ingress of liquids

• Use aluminum or stainless steel materials where possible

• Have load-bearing surfaces plated or coated to withstand caustic liquids

Environmental challenge: Solid particulates

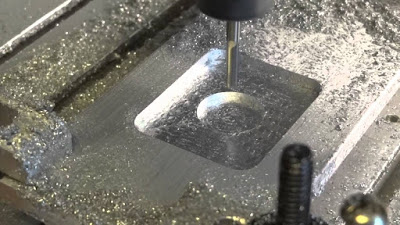

Metal and wood chips tend to be larger than glass or ceramic dust, but are still detrimental to recirculating bearings.

Image credit: Inventables.com

Like liquids, solid particulate contamination spans a wide range of types—from large metal or wood chips, to extremely fine glass or ceramic dust. Linear bearing and screw manufacturers have mostly perfected seal and scraper designs to protect against solid contaminants that fall onto bearing surfaces. But when the contamination is highly airborne, a completely sealed unit—such as an enclosed linear actuator with a positive sealing mechanism—is the best option. For even further protection, positive air pressure can be piped into the actuator to prevent contamination from entering and settling inside.

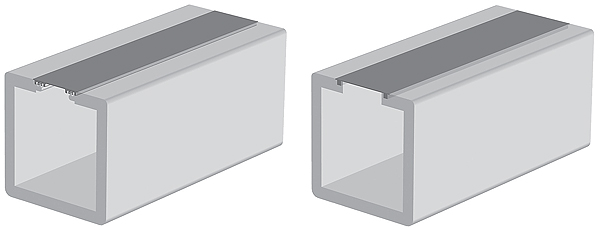

Linear actuators with tightly sealed enclosures are ideal for protecting against fine particulates.

Image credit: Thomson Industries, Inc.

Solutions

• Use scraper-type seals on linear guides

• Use full-contact seals on ball screws

• When possible, use fully sealed linear actuators with (slight) internal pressurization

Environmental challenge: Extreme temperatures

Temperature considerations include extremely high or low temperatures, as well as large temperature fluctuations that the system may experience over a short time period. Extreme temperatures tend to have the greatest effect on plastic components, such as seals and recirculation mechanisms. If the temperature exceeds the upper or lower limits of the standard plastic material, most manufacturers offer alternative materials, such as Viton®. Lubrication—particularly grease—can also be affected by extreme temperatures. Temperatures above or below the lubrication’s rating can cause its components (base oil, thickener, and additives) to separate and reduce its effectiveness. And choosing a lower-viscosity lubrication will help mitigate heat generated by the recirculating balls inside the bearing or screw.

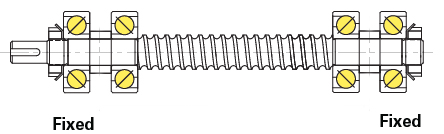

Mounting a ball screw in tension, with fixed bearings on each end, can help mitigate thermal expansion.

Image credit: NOOK Industries

Aside from extreme temperatures, fluctuations in temperature can be detrimental in two ways. First, large or frequent temperature changes can cause condensation to form, which can result in corrosion. Second, temperature fluctuations can cause thermal expansion and contraction in steel and aluminum. This is especially problematic for ball screw assemblies, because any change in the length of the screw has a negative effect on its lead accuracy. Forced air cooling across the ball screw is the simplest remedy for thermal expansion, but more reliable methods are to provide internal cooling, or to mount the screw in tension.

Solutions

• Use plastics that can withstand extreme temperatures

• Ensure lubrication (especially grease) is rated for the expected temperature range

• Provide cooling for ball screw assemblies

• Mount ball screw assemblies in tension

Filed Under: Actuators, Bearings, Ballscrews • leadscrews, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!