The EtherCAT Technology Group (ETG) released ETG.5003-1 device standard for the semiconductor industry. This standard has nine corresponding specific device profiles to aid engineers in the design of tools in the semiconductor industry.

The ETG Semiconductor Technical Working Group during a meeting in Santa Clara, Calif., specified 10 new device profiles for the semiconductor industry.

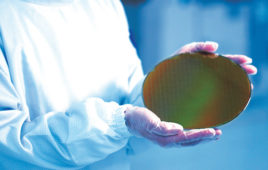

With these device profiles, EtherCAT can be used for more than just motion control, I/O, sensors, and gateways in semiconductor manufacturing machines. Industry specific devices such as mass flow controllers or vacuum valves can be implemented directly into the EtherCAT system. On the technical side of this process, Florian Häfele supervises the ETG Semiconductor Technical Working Group and explains: “Since the release of the device profiles developed in 2012, we responded to machine builders’ demands to establish EtherCAT in the semiconductor industry as well to facilitate the creation of new industry-specific devices. We expect that EtherCAT will be found in nearly all tools, at the very latest when the 450 millimeter wafer diameter standard has been adopted for all semiconductor manufacturing machines.”

The new profile, ETG.5003-1 (Common Device Profile = CDP) describes the general requirements for devices that are published within the specification series ETG.5003. At the moment this concerns nine different device types, which are defined in the Specific Device Profiles (SDP). Together with the CDP they provide the starting point for a new generation of devices that will enable the design of more advanced machines of the future. The benefits of the new standard are simple: in EtherCAT, even devices from different manufacturers are now equal regarding their data structures and synchronization modes. This makes replacement and handling easier and significantly more understandable for tool manufacturers. Additionally, the industry-specific devices will get a unique look and feel as a result.

That the profiles were finished in a relatively short amount of time was due in large part to the strong commitment within the semiconductor industry: companies like Applied Materials, Lam Research and Tokyo Electron not only participated actively in the specification process, but also encouraged their device suppliers to take part in the ETG Semiconductor Technical Working Group.

EtherCAT Technology Group (ETG):

EtherCAT

www.ethercat.org

Filed Under: Semiconductor manufacture

Tell Us What You Think!