By Carl Bostrom, Senior Applications Engineer, Bosch Rexroth, Hoffman Estates, Ill.

By integrating event-driven strategies into motion control software programming, automation systems can be optimized beyond what’s possible with traditional electronic cams or motion profiles.

Servomotors have largely replaced mechanical cams as the standard means of meeting the motion demands of the automation industry. The reasons are well known; mechanical simplicity and system configurability are the two most common, but improved synchronization, ease of machine servicing and elimination of wear and tear on parts, among other benefits, are often cited as well.

Still, even when not physically present, the influence of mechanical cams can still be felt. Cams continue to shape the way we approach machine building and the way we program our automation systems; we tend to think in terms of “electronic cams” and their associated cam tables. To some extent, this makes sense. Packaging machines, for example, often require repetitive motions and in these cases, the cam paradigm serves us well. However, in many situations, we fail to take full advantage of process information already present in our system, so machines tend to be repetitive when they could be adaptive instead.

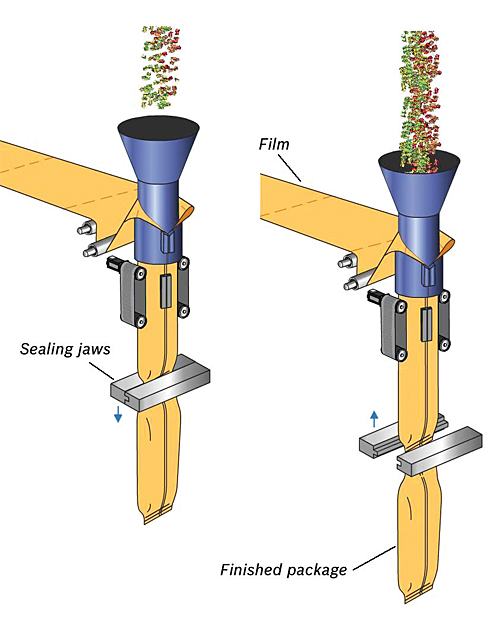

A dynamic sealing mechanism typical of a vertical form-fill-sealing (VFFS) machine showing the sealing jaws.

One way that controls and machines are becoming more adaptive is exemplified by Bosch Rexroth’s Flex Profile. Flex Profile is a segment-based cam technology that can help implement adaptive strategies by incorporating event handling directly into the Flex Profile object definition. Also key is the ability to define segments based on synchronization constraints. For example, a segment can be defined that prescribes an axis return to a given position at a specified velocity and acceleration once the master axis reaches some threshold, say 360º.

Cam vs. Event-driven model

Here’s a comparison between a traditional cam-based model and an event-driven model from the packaging world; the vertical form-fill-sealing (VFFS) machine.

A dynamic sealing mechanism on a typical VFFS machine works this way; during the sealing operation, the mechanism travels together with the film as it’s fed downward. After the sealing operation is completed, the jaws open and the mechanism returns upward to its starting position for the next cycle.

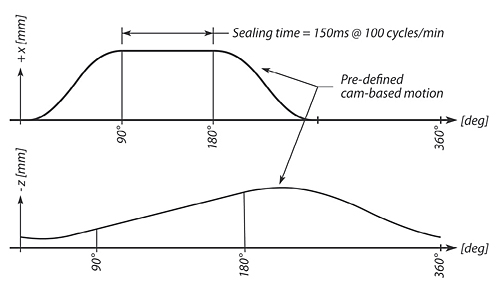

Using the cam model allows predefining a sealing time of 150 ms and defining cam profiles based on the current machine speed.

Following the cam paradigm, we might approach our programming task by predefining the x and y motions of the mechanism via cam tables. Here the motions would be defined according to our knowledge or assumptions of the process requirements. For example, we could predefine a sealing time of 150 ms and define cam profiles based on the current machine speed accordingly.

This method might be acceptable in situations where the sealing process was reasonably consistent. In case of format or process changes (e.g. longer bag length or increased sealing time), cam tables could be recalculated to accommodate the new requirements, but these changes could not be realized during the current machine cycle. At best, the new motions would be loaded into a memory buffer and would be available for activation only in later machine cycles. Also, abrupt changes in film feed speed could result in over-sealing or under-sealing.

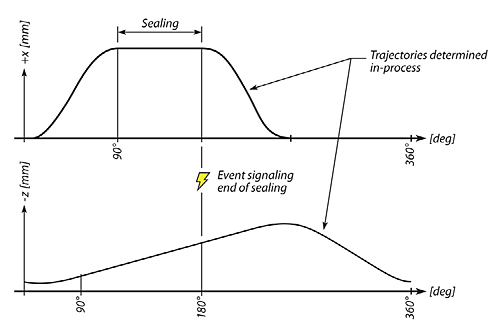

Adaptive control, following the event-driven model, allows for trajectories to be determined in process, based on real-time events.

An event-driven model takes a different approach. Suppose instead that our machine could monitor the sealing process; for example, by means of a thermocouple mounted to the sealing surface or an external timer, and broadcast when this process was complete. Optimally, we would then immediately open the sealing jaws and return to our start position in preparation for the next cycle. Doing so would minimize total travel, resulting in lower average velocities over the machine cycle at a given machine cycle rate. Note that such a scheme requires that the motion be defined with a certain amount of flexibility built in. First, we must be able to respond to the external event itself. Additionally, we must be able to compensate in-process to the variability implicit in any event-driven scheme. In other words, the motion plan must be able to adjust automatically regardless of when our trigger event comes. Note that the cam approach as described previously cannot realize this optimization since changes to the cam motions only take effect in later machine cycles.

Flex Profile

Flex Profile provides a comprehensive framework in which to address the demands of the form-fill-seal application described previously. Each Flex Profile is defined as a collection of segments or steps. These segments are of two types: Standard, in which the motion trajectory is pre-specified mathematically, and Flex, in which the motion is defined by some goal or restraint. In the case of standard steps, the drive is commanded to move a certain distance or hub as the master moves within a defined range. This motion proceeds according to a specified motion law; the motion law generates a trajectory between the specified boundary conditions. Note that master axis may be a real or virtual axis, or the master may be time-based.

The Flex segments are defined somewhat differently. One still provides a motion law, but rather than defining the trajectory explicitly, one specifies a goal. For example, one might require that the axis, regardless of its current position, reach a certain target once the master crosses some specified threshold. Alternately, one might require that the axis reach some position over the next 90 degrees of master travel. The motion trajectory itself is not specified, only the final outcome.

Other features of Flex Profile

Flex Profile is a control-side technology included as standard in all Rexroth MLC motion-logic controls. Flex Profiles, including their associated events, may be defined using the Rexroth Cam Builder graphical interface or, in cases where end-user or recipe-driven input is required, programmatically.

Key features of Flex Profile include the ability to combine synchronous and time-based steps in a single data structure, well-integrated event handling, and the so-called Flex Steps that are calculated in process to adhere to a specified end-point constraint. Other features include:

• Support for most well-known motion laws, including poly5, poly7, modified sinusoid, modified trapezoid, etc.

• Easy inclusion of additional, user-defined motion laws

• Legacy support for tradition cam tables

• Well-integrated graphical editing/analysis tool

• Single-cycle or endless execution

• Automatic and configurable synchronization of the slave to the master

Applying Flex Profile to VFFS packaging equipment

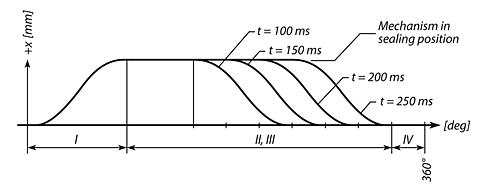

Returning to the VFFS example, the horizontal motion of the sealing mechanism is a function of the film position. Because we must only come into contact with the film once the speeds of the mechanism (in the vertical direction) and the film match, the first segment is defined as a synchronous segment. The next segment is defined as a time-based step whose length is given as the maximum possible seal time. In this case, the end of the sealing process will be triggered by an external timer or some process monitor. The maximum seal time is used here to define the default behavior of the Flex Profile. The sealing bars then open, again according to a time-based master, which is to say at a defined rate of speed. The duration of the final step, in which the sealing bars are fully open, is calculated internally by the system. This is the so-called “flex step,” during which we transition from a time-base step back to being fully synchronized with the real or virtual master.

The graph describes the horizontal motion of the sealing mechanism in a VFFS machine as a function of the film position.

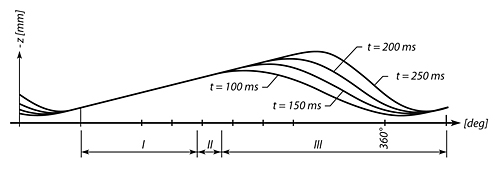

The vertical motion of the sealing mechanism is also defined as a function of the film position. Here all Flex Profile segments are synchronous with the master. Step I defines the vertical travel of the mechanism as it tracks the film; this is the step in which sealing occurs. When our external event signals the end of the sealing process, we abort step I and transition immediately to step II, during which the mechanism travels with the film for a short distance to allow the jaws to open. In step III the jaws return upward to their starting position. As in the previous case, the final step is a “flex step,” meaning that the system automatically calculates a trajectory such that we return to our defined start position at a fixed master position.

The graph shows how the vertical motion changes as a function of the event timing. If the event does not occur, the default trajectory is followed.

Using adaptive control has quite a few benefits. For one, adaptive control shortens motion trajectories whenever possible, resulting in energy savings. It also helps to reduce wear and tear on mechanical parts because higher-order motion laws minimize jerk and acceleration, leading to longer mechanism and machine life. Adaptive control can also reduce material waste because good control schemes and real-time information response tend to provide greater system efficiencies resulting in fewer rejects. Another benefit is higher throughput, as eliminating unnecessary movements leads to higher machine speeds. Adaptive control can also help simplify coding. With a comprehensive programming framework for motion, code is simplified and made more re-usable.

Bosch Rexroth

www.boschrexroth-us.com

Filed Under: Packaging, Motion control • motor controls

Interesting process