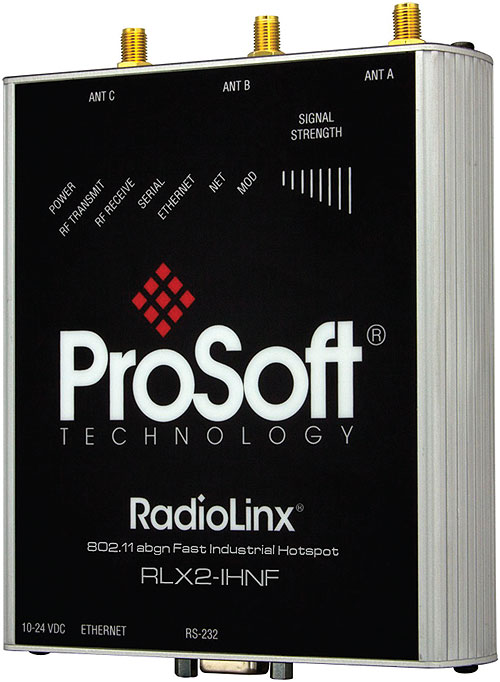

The 802.11abgn Fast Industrial Hotspot (RLX2) features client/bridge fast roaming between access points, Ethernet packet optimization, and enhanced diagnostics. These capabilities deliver seamless high-speed Ethernet connections for moving machines and vehicles traveling long distances in assembly plants, crane systems and mining. The secure, high-speed wireless network reduces project costs, while eliminating mechanical festooning, rails and slip rings in mobile applications.

The Fast Industrial Hotspot offers wireless networking and reduces project costs, while eliminating components in mobile applications.

The radio’s Fast Roaming technology uses less than 50 ms time between access points and provides full device bridging. The module provides secure 802.11i and 128-bit AES Encryption and operates securely in the 2.4 GHz or 5 GHz bands. The microSD card will automatically store/load configurations, reducing down time.

The Hotspot is designed for extreme environments and hazardous locations, including oil and gas systems. It is a suitable wireless system for Producer/Consumer PLC/PAC networking, remote I/O, safety I/O, plant backhaul networking, remote video and mobile worker connectivity. It works over operating temperatures of -40 to +75°C (-40°F to +167°F) and has agency approvals and certifications with Class1, Division 2 and ATEX Zone 2. The module is high shock/vibration tested.

ProSoft Technology, Inc.

[email protected]

Filed Under: Slip rings + rotary unions, ELECTRONICS • ELECTRICAL

Tell Us What You Think!