Ferrule-Lock has introduced a vibration-proof, locknut system. The versatile three-piece locknut technology provides greater holding power than other locknut systems for high-vibration applications.

Excluding improper joint design, vibration is the most common cause of joint failure. Ferrule-Lock’s patented design utilizes a simple and effective innovation borrowed from the tube fitting industry that is easy to install and outperforms other locknut fasteners.

Excluding improper joint design, vibration is the most common cause of joint failure. Ferrule-Lock’s patented design utilizes a simple and effective innovation borrowed from the tube fitting industry that is easy to install and outperforms other locknut fasteners.

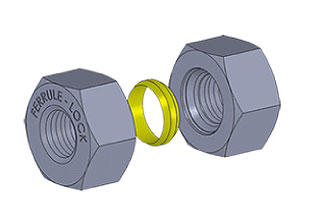

Ferrule-Lock is a three piece system comprised of two identical Ferrule-Lock nuts and a Ferrule. The bolt is customer supplied to meet the application. The first Ferrule-Lock nut is threaded onto the bolt and torqued to the designed clamp load and standard specifications. The Ferrule is slipped over the bolt and seated in the champhered face of the clamp nut. The second, Ferrule-lock nut – acting as a jam nut -is threaded onto the bolt until the Ferrule seats into the champher of the jam nut. The final step is to tighten the jam nut to compress and bind the Ferrule into the two Ferrule-Lock nuts. This creates a joint that will not vibrate loose.

The Ferrule-Lock system has been rigorously tested using the Junker test. The testing procedure consists of a fastened joint between a stationary and a movable plate. A load cell is placed on the bolt and the two plates are fastened together under a specified clamp load and subjected to vibration using an amplitude of 10% of the diameter of the bolt and 12.5 hertz. for 1000 cycles.

An added benefit of the Ferrule-Lock system is that the load on the clamp nut has no impact on the vibration proof quality of the Ferrule-Lock system. The only requirement is that the Ferrule be compressed between the opposing Ferrule Lock nuts. This feature is very useful in applications where minimal clamp load is required.

Ferrule-Lock is designed to provide a serviceable joint. It is a simple matter of loosening the jam nut, removing and discarding the Ferrule, and removing the clamp nut as you would normally. The Ferrule-Lock nuts are reusable with a new, replacement Ferrule.

Ferrule-Lock

www.ferrule-lock.com

Filed Under: Screws • nuts • bolts, FASTENING • JOINING • locks • latches • pins, Shocks + vibration control • gas springs

Tell Us What You Think!