If you’re attending the Robotics Summit/DeviceTalks Boston 2019, look for Festo solutions that reduce engineering effort for state-of-the-art robotic systems — including laboratory automation. Festo will also show a hands-on bionic learning kit at Booth #216 for middle and high school students.

Topping off its display, Festo will fly its Bionic Learning Network flying insects — the BionicOpter dragonfly and independent-group-flight eMotion butterflies. Flights are scheduled at the Festo booth for:

June 5 from 5 to 6 p.m.

June 6 from 11 to 11:30 a.m.

Festo has technically mastered the highly complex flight characteristics of the dragonfly, employing lightweight construction and function integration. The ultralight BionicOpter can fly in all directions, hover in mid-air, and glide without beating its wings. eMotion butterflies combine the ultralight construction of artificial insects with the coordinated flying behavior of a collective.

Festo eMotion butterflies demonstrate group-flight characteristics.

Ten cameras record the butterflies using the robots’ infrared markers. The cameras transmit the position data to a central master computer, which coordinates the butterflies group flight. The intelligent networking system creates a guidance and monitoring system that could be used in the networked factory of the future.

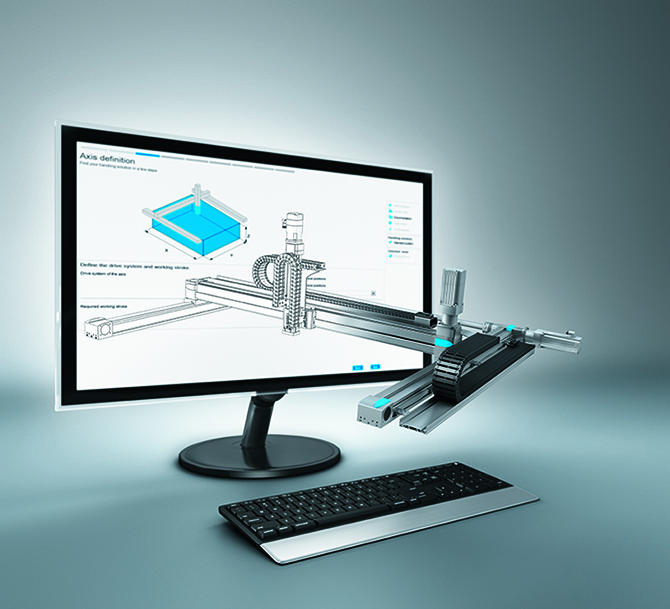

Design tools in the form of software

With the Festo Handling Guide Online, engineers can design single axis, 2D, or 3D Cartesian robots and receive CAD files in as little as 20 minutes. The robots are delivered either as subassemblies or as kits. Seamlessly and automatically, the new Festo Motion Control Package (FMCP) designs the robot’s control panel using data generated from the Handling Guide Online session. After delivery, it requires just a few hours to add power to the control panel and configure the robot’s motion profile.

The Festo Handling Guide Online lets design engineers build Cartesian robots in as little as 20 minutes.

Liquid dosing display

Festo demonstrates a laboratory automation application for rapid, precise liquid dispensing using a Cartesian robot liquid valve manifold. In this demonstration, an EXCM planar surface gantry equipped with a VTOE eight-liquid valve manifold with 9 mm pitch channel fills an entire row of microwell plates simultaneously. One valve for each nozzle allows for independent control of each of the eight channels for high precision and greater flexibility. The EXCM planar surface gantry is suitable for any space constrained pick-and-place, assembly, and laboratory automation application. The EXCM planar surface gantry is fast, accurate, modular, and flexible in X/Y/Z motion. It is also plug-and-play for quick and easy start up.

Electric actuators for miniature applications

The new, low-cost linear axes ELGC and mini slide EGSC electric actuators are used for applications where compact dimensions are essential. These axes can be combined into space-saving handling systems that fit seamlessly into assembly, test and inspection, small parts handling, and desk top applications. They offer an optimal ratio between installation space and working space. The axes and mini slide feature a common system approach, platform architecture, and adapter-less connections.

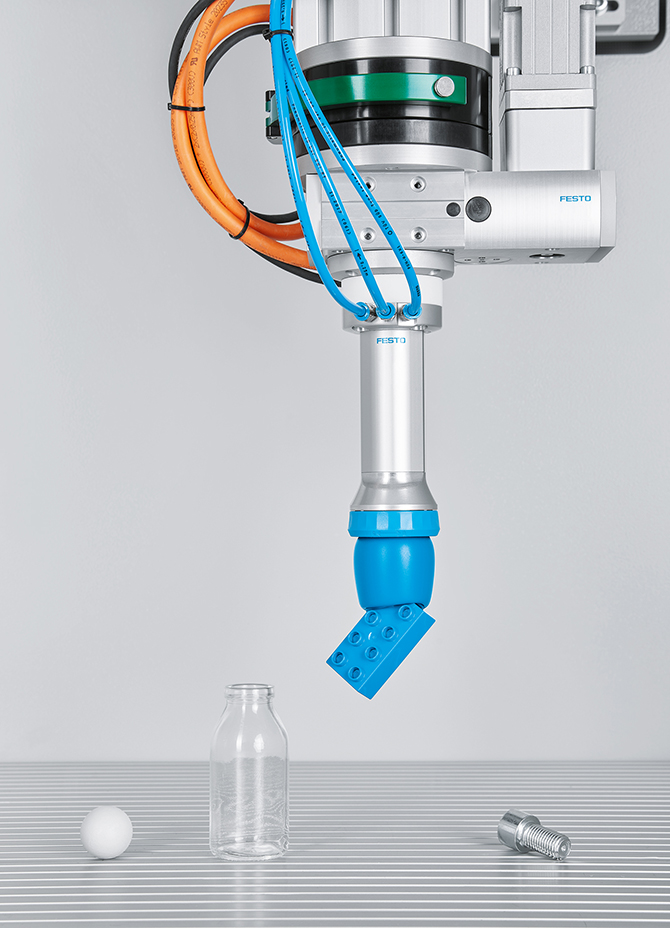

Adaptive grippers form around various object shapes

The new DHEF adaptive shape gripper offers maximum gripping flexibility with minimal engineering. The adaptive shape gripper automatically grips mixed objects with multiple shapes, unaligned objects, and numerous objects at once.

The Festo DHEF adaptive shape gripper handles a range of products with diverse geometries.

The gripper gently forms around an object and is suitable for gripping fragile items. It is suitable for human-machine interaction. The DHEF adaptive shape gripper is the industrial version of the Bionic Learning Network’s FlexShapeGripper, which models the gripping mechanics of a chameleon’s tongue. The lizard’s tongue darts out at its prey and then pulls it in while the outside edges wrap around the target, securely holding it. The DHEF adaptive shape gripper uses a flexible silicone cap as the tongue device that draws an object in and captures it.

Festo shows adaptive gripper fingers DHAS for transferring or sorting fragile, oddly shaped, or tightly packed products that rigid grippers or vacuum cups can’t easily handle or cost too much for the intended use. Applications include transferring parts from tight packaging, handling sensitive parts such as filter cartridges, picking unevenly shaped products such as avocados, moving parts to humans at manual assembly stations, conforming to parts with various diameters, and more. The concept of the DHAS derives from the flexible movement of a fish’s tail, what Festo calls the Fin Ray Effect. The gripper fingers wrap around objects with a wave-like motion. Traditional parallel grippers will also be on display.

The Festo adaptive gripper fingers DHAS gently conforms to the shape of the object it’s gripping.

The Festo EHMD rotary gripper module is suitable for laboratory automation applications such as fitting and removing vial caps. The EHMD also picks and places small parts from trays. With the addition of the CMMO-ST motor controller, the EHMD module delivers flexible gripping under power. Gripping can be implemented either electrically with a stepper motor or pneumatically using a cylinder.

Bionics kit for educational programs

The Bionics Kit, for students between 14 and 18 years old, gives teens the opportunity to solve problems using bionic methods in a creative and uncomplicated way by building a bionic fish, a chameleon gripper, or an elephant’s trunk with adaptive gripper. The kit contains all the components necessary, including conventional small servo motors, electronics components, and plastic elements. In addition to the hardware, a free-of-charge learning environment can be found at www.bionics4education.com. The site supports the pupils by providing more content about bionics as well as helpful tips on practical implementation in lessons or at home. There are also training videos, software codes, and CAD data for producing components on a 3D printer.

For more information, visit Festo at the Bionics Learning Network website.

You may also like:

Filed Under: 3D printing • additive • stereolithography, Pneumatic equipment + components, Software • simulation, ENGINEERING SOFTWARE, Student programs, LINEAR MOTION, MOTION CONTROL, MORE INDUSTRIES, Motion control • motor controls, Motors • stepper, Robotics • robotic grippers • end effectors