Five finalists have been announced for the inaugural Leadership in Engineering Achievement Program (LEAP) Awards’ Mechanical Category. These finalists have created and incredible mix of mechanical component technology advances. The daunting task of judging this highly competitive category went to a panel of independent technical/engineering-oriented judges. Responsible for the Mechanical category were these four judges:

Five finalists have been announced for the inaugural Leadership in Engineering Achievement Program (LEAP) Awards’ Mechanical Category. These finalists have created and incredible mix of mechanical component technology advances. The daunting task of judging this highly competitive category went to a panel of independent technical/engineering-oriented judges. Responsible for the Mechanical category were these four judges:

Russ Hempstead

Russ Hempstead

Senior Development Engineer

Just Right Surgical

Russ Hempstead has been working in the medical device industry for more than 25 years. He has focused on early-stage design and development through manufacturing of class II medical devices. Biomedical engineering was an obscure specialty when he attended college, so he pursued his degree in mechanical engineering with an emphasis in polymer science.

Hempstead has extensive experience in clinical settings for the purposes of early concept generation, as well as product launch. Clinical settings include animal and cadaver labs for product validation activities and hospital operating rooms for procedure familiarization and observation. He has led engineering teams in various facets of device development and manufacturing for the last 13 years. In all of those instances, he was an individual contributor in addition to the project manager. Hempstead has been considered a subject matter expert in the areas of plastic material selection for biocompatibility and sterilization, design for injection molding, design for manufacturability, and finite element analysis.

Thomas E. Manley

Thomas E. Manley

Engineering Manager

Feedall Automation

Thomas Manley is Manager of Engineering at Feedall Automation, where he directs and designs the machine orders that come through the engineering department. He is also a part-time engineering instructor at Lakeland Community College and is the designer of 14 U.S. Patents for various companies that he has worked for.

Manley has worked with high-profile companies such as Harley-Davidson, American Axle, Meritor, Caterpillar, and Ford Motor Company, among others. He helps companies and engineers implement automation systems into their plant, while adhering to their desired budget and goals.

Russell Olmsted

Russell Olmsted

Project Engineer

Arrow Tech Company

Russell Olmsted is a Mechanical Engineer with experience in product development, product management, and distribution sales. He also has expertise in compressible and in-compressible fluid applications, fluid power applications and components focused on filtration, pump, and motors, and specialty and compressed gas components.

Olmsted is currently a Project Engineer at Arrow Tech Co., where he reviews and evaluates current work-flow processes with Arrow Tech and M&D Welding daily. His expertise involves developing contact-record-management (CRM) capabilities, providing technical support to marketing and operations to resolve any issues with existing products, and developing solutions to production problems related to materials, processes, and tooling.

Tom Solon

Tom Solon

Director of Sales and Marketing

RH Murphy Co. Inc.

Tom Solon has a diverse engineering background in roles as both an OEM and supplier, spanning many industries, from housewares and consumer products, to semiconductor manufacturing and medical equipment technology. A recognized authority in linear motion products, plastics, and semiconductor handling, Tom has authored numerous articles and technical papers.

Tom earned his BSME in Machine Design and BA in Economics from Brown University and is a licensed Professional Engineer. He devotes much of his free time to public education as a school board member and technical education advisory board member.

Below are descriptions of the five finalists. The overall winner of the Mechanical category will be announced at an awards dinner on December 11th in Costa Mesa, Calif.

Colder Products Company

Ultra-Compact LQ2 Quick Disconnects

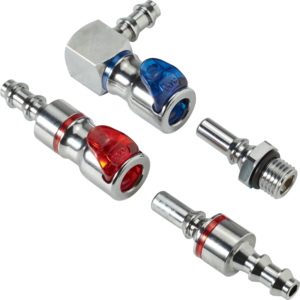

The LQ2 Series connectors are an addition to CPC’s liquid cooling of electronics connector products. For liquid cooling systems, the small, compact LQ2 connector is perfect for use in applications such as high-powered PCs, data centers or medical equipment that require ultra-reliable, drip-free connections and disconnections. The LQ2 is specifically designed for the liquid cooling market where applications require multiple connect/disconnect cycles and liquid loss and air introduction back into the system are not desired.

The LQ2 Series connectors are an addition to CPC’s liquid cooling of electronics connector products. For liquid cooling systems, the small, compact LQ2 connector is perfect for use in applications such as high-powered PCs, data centers or medical equipment that require ultra-reliable, drip-free connections and disconnections. The LQ2 is specifically designed for the liquid cooling market where applications require multiple connect/disconnect cycles and liquid loss and air introduction back into the system are not desired.

The LQ2 has the highest flow capacity on the liquid cooling market of any 1/8-in. connector. The higher flow capacity provides a reduced pressure drop, so your fluid handling systems do not work as hard. Like all LQ Series products, the LQ2 uses multilobed seals that ensure connector reliability.

The seals provide further protection against debris since the first lobe collects the debris with the additional seals adding another layer of protection. With a contoured thumb latch, the LQ2 makes it easy for one-handed, quick connections and disconnections. It has a sleek, ergonomic look with a low profile and smooth lines making it easy for users to grip. Other advantages of the product include color coding for foolproof connections (red for hot, blue for cold) and ¼-in. SAE and hose barb terminations.

R+W Coupling Technology

World’s Largest Ball-Detent Safety Coupling

Sometimes the best product developments are borne of a specific customer demand. In 2016 R+W was contacted for precision mechanical overload protection by a company building a transmission shaft for a pair of six megawatt motors to be installed in a wind energy test facility. R+W was the only manufacturer willing to take on this challenge and began its seven-month development process in July of 2016, for delivery approximately one year later.

Sometimes the best product developments are borne of a specific customer demand. In 2016 R+W was contacted for precision mechanical overload protection by a company building a transmission shaft for a pair of six megawatt motors to be installed in a wind energy test facility. R+W was the only manufacturer willing to take on this challenge and began its seven-month development process in July of 2016, for delivery approximately one year later.

Weighing in at 21.5 metric tons, and made from custom forgings, this safety coupling was designed for a disengagement torque of up to 20,000,000 Nm. The basic concept is that of the modular ball-detent safety element coupling. When a torque overload occurs, drive balls protruding from the modules are pushed back into their housings by conical detents in the driven flange of the clutch, disconnecting the driveline rapidly and repeatably. Locking segments inside the housings hold the balls back until they are mechanically released to reload the system after the overload event has passed. In this case 36 of a new higher capacity module were mounted near the rim of a 4-meter diameter clutch.

Starting with a detailed 3D model, R+W engineers used FEA to find possible weaknesses in the coupling which would not usually occur in conventional sizes. “We have been extremely meticulous in checking for the danger of deformation or cracks due to extreme loading in the wind energy test facility. The long-term functional safety of the coupling depends on this,” adds Rainer Benz, Technical Director at R+W.”

Rolling Motion Industries

Traction Drive Technology

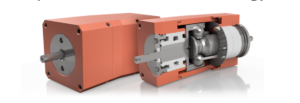

We offer a new patented technology that is going to be a game changer in many industries. Traction drives have been around for over 100 years, but they were complex and expensive. What we offer is simple and cost-effective. Our technology gives smooth, quiet, efficient and accurate rotation. These offerings solve current problems in the industry, and RMI is the solution. With the use of the most modern CNC equipment and precise tooling at our partner/manufacturer FCS, we can handle any quantity, any size drive, and any application.

We offer a new patented technology that is going to be a game changer in many industries. Traction drives have been around for over 100 years, but they were complex and expensive. What we offer is simple and cost-effective. Our technology gives smooth, quiet, efficient and accurate rotation. These offerings solve current problems in the industry, and RMI is the solution. With the use of the most modern CNC equipment and precise tooling at our partner/manufacturer FCS, we can handle any quantity, any size drive, and any application.

Due to the simplistic design of our patented product we are able to penetrate many markets. In most circumstances, a superior product means a much more expensive product, but this is not the case with RMI. Simplicity is the essence of brilliance is a saying and our patented technology sure fits that category. RMI started as a visualization of a new way to get to point B.

This new traction drive from Rolling Motion Industries called the RMI Marmalade includes six moving parts — a cup shaft component, a toroidal shaft component, twin precision-matched bearings for shaft support, one pair of rolling elements between the shaft elements, and engineered traction fluid to help the balls transmit torque. The engineered traction fluid inside the sealed housing works for power transmission and cools and lubricates the drive. A microscopic gap between the rolling elements lets the fluid slip through — but as the fluid squeezes through this microscopic gap, high pressure causes the fluid to temporarily solidify. Then the solid structure of the fluid transmits torque from input to output shaft. Material science has enabled this new traction drive mode of operation. Traditional traction-drive fluids have friction coefficients of 0.05 to 0.06. The new drive employs fluid with coefficients of friction of 0.1 to 0.12 — particularly useful for the transfer of torque through smaller normal forces … even with operation that makes slippage between input and output shafts impossible.

Twin Spring Coupling

TSC500 flexible coupling unit

The patented Twin Spring Coupling is a twin torsion spring coupling unit. The counter wound springs allows the coupling to pass torque in both forward and reverse.

The patented Twin Spring Coupling is a twin torsion spring coupling unit. The counter wound springs allows the coupling to pass torque in both forward and reverse.

With no internal components except a single ball bearing the torque is transferred through the input hub and spring tightening down on the internal spring transferring the torque through the ball bearing to the output shaft, the tightening turns the springs effectively into a flexible yet solid shaft. This allows almost 100% of the input torque to be transferred to the output.

The same process also happens when the product is used in the reverse direction, except the inner spring tightens down. The product can be used at high and low speeds allowing it to be used across all industry sectors. Because the product contains only a single ball bearing the factory lubricated unit can be used without the need for constant regreasing as is required by both universal and CV joints, saving money and time.

As it is constructed of springs the ability for the unit to operate at higher angles than current industry technology can also achieved. Its simple design also means it can be used in environments like water, mud, dirt, dust and any other hostile environment where bearings would be destroyed when exposed to these contaminants. It is currently available in both 300 and 500hp versions.

WITTENSTEIN

Rack Assembly in Minutes, Chipless Pinning with INIRA

WITTENSTEIN has patented a system for the simple, safe and efficient assembly of racks. INIRA clamping and INIRA adjusting make the assembly of racks much faster, more accurate and more ergonomic. INIRA pinning is setting new benchmarks and further revolutionizing rack assembly. Traditional pinning methods are immensely time-consuming. Precision bores have to be drilled and then the chips have to be carefully removed from the component. INIRA eliminates the chips, reducing assembly times while increasing safety considerably.

WITTENSTEIN has patented a system for the simple, safe and efficient assembly of racks. INIRA clamping and INIRA adjusting make the assembly of racks much faster, more accurate and more ergonomic. INIRA pinning is setting new benchmarks and further revolutionizing rack assembly. Traditional pinning methods are immensely time-consuming. Precision bores have to be drilled and then the chips have to be carefully removed from the component. INIRA eliminates the chips, reducing assembly times while increasing safety considerably.

97.78 % time savings

Simple pinning of the rack in one minute instead of 45 minutes in previous cases.

No drilling, no reaming, no chips.

INIRA pinning is safer, faster and more efficient because there are no chips to clean up after assembly.

Exceptionally easy assembly

Assembly work significantly reduced. Easy to handle in any mounting position.

Suitable for any application requiring rack installation.

Filed Under: Coupling Tips

Tell Us What You Think!