FORT WAYNE, IN – Trelleborg Sealing Solutions offers Flexcoat‚â„¢ coatings and surface treatments to improve friction characteristics of elastomer seals, especially important in automated assembly.

Trelleborg Sealing Solutions developed the Flexcoat‚â„¢ range of coatings and surface treatments to give optimum friction characteristics and enhance the performance of elastomer seals. Benefits are also provided when seals are fitted in plug fit and quick release couplings and allow elastomer seals, usually recommended for static applications, to be used in low-speed and short stroke length dynamic situations.

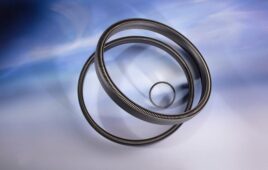

The way seals perform depends on more than just the material they are made of. What’s on the surface matters as well. The tendency of elastomer seals to stick to mating counterparts makes them less suitable for dynamic situations and assembly operations where insertion is required. Seals are also inclined to adhere to one another, making automated assembly difficult. To solve these problems, Flexcoat‚â„¢ can be applied to seals, improving their friction characteristics.

The performance characteristics of surface treatments are evaluated in the Trelleborg Sealing Solutions research and development laboratories in Europe and the Americas. They undergo assembly, endurance and friction tests. In all cases, results for a variety of commonly used elastomers are recorded.

::Design World::

Filed Under: Seals • O rings, Seals

Tell Us What You Think!