TE Connectivity has launched the new FORGE power drawer connector for high-current and high-voltage power supplies and power distribution systems. This blind-mateable connector, produced from a scalable mold platform, allows users to specify the connector configuration that best meets their design requirements. With a voltage rating of up to 1000V AC or DC, coupled with a robust design, the product is well suited for high-efficiency power conversion applications and high-reliability power systems used in rugged environments. Target applications include power inverters, servers, switches and routers used in data centers, alternative energy power conversion, and military and aerospace products.

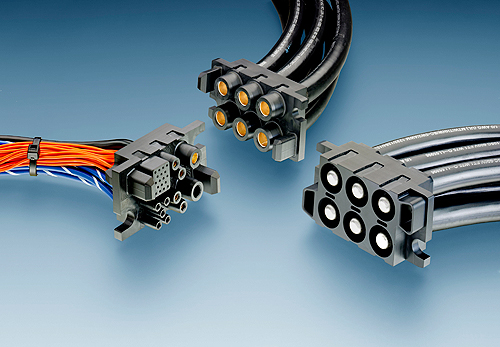

With a scalable mold platform, the FORGE power drawer connector allows users to specify the number of modules on its housing as well as the size and location of its contacts. Housings can be designed in two-row, one-to-five column configurations for a maximum of 10 modules and a current carrying capacity of over 1000 Amps (dependent on configuration). This customizability allows TE to quickly deliver a power connector to help shorten design time and save design space.

An added benefit of the FORGE power drawer connector is its use of POWER ARCH contacts – highly conductive contacts, also manufactured by TE, which allow for a much lower mating force than drawer contacts currently offered in the market. This low mating force enables easy mating for a secure connection and helps to reduce potential damage during mating/unmating cycles.

Contacts are touch-safe and available in five different sizes with current ratings from 3 Amps to 250 Amps per contact. Additionally, the product offers three mating sequences for use in hot-plug applications. The contact sequencing helps to control power arcing during mating and unmating.

TE Connectivity

http://www.te.com/products/FORGEdrawerGO

::Design World::

Filed Under: Aerospace + defense, Connectors (electrical) • crimp technologies, Power supplies, ELECTRONICS • ELECTRICAL

Tell Us What You Think!