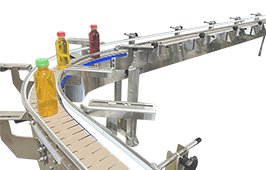

The new tight turning radius option on Dorner’s FlexMove Helix Conveyors allows for compact turns with a diameter of spiral measuring 1,000 mm (39.4 in.) at centerline. The advantage this new tight turning radius option brings to customers and their facilities is even greater flexibility in layout for applications such as accumulation, buffering, cooling product and more. The small footprint also solves tight production line space problems.

The tight turning radius option is available on D-Tools, Dorner’s online conveyor configurator. D-Tools allows users to download 2D and 3D CAD models of the conveyor to construct simple or complex FlexMove Helix conveyor packages, as well as individual components such as gearmotors and mounting packages, support stands and accessories.

FlexMove Helix Conveyors feature a reinforced frame structure for added strength and durability. Helix Conveyors can be set at incline angles of up to 7° with a flat top chain and up to 10° with a friction top chain. Helix Conveyors offer a variety of options and accessories, including two end-transfer options: a roller transfer plate, or a powered transfer plate for smooth transfer of parts as small as 3 in. in diameter. Helix Conveyors can accommodate loads up to 136 kg (300 lb) and speeds up to 52 m/min (171 ft/min).

All Helix Conveyors are custom built-to-order and delivered in about 30 days.

Dorner

www.dornerconveyors.com.

You may also like:

Filed Under: Conveyors