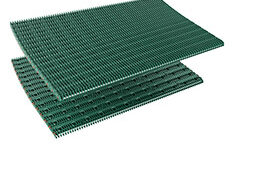

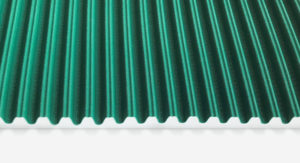

Gates, a provider of application-specific fluid power and power transmission solutions, has announced the introduction of two new thermoplastic polyurethane (TPU) belts, the Gates Parabolic Pitch (GPP) in 8 mm and 14 mm profiles. The new GPP belts are stronger, more durable, quieter, safer to operate and require less maintenance than other alternatives, including alternative rubber belts, roller chains and steel cables.

“At Gates, we’re continually in search of market opportunities where our materials science expertise and drive to innovate can create added value for our customers. The new GPP belts are the latest examples of our efforts,” said Scott Manley, general manager, Gates TPU. “In addition to expanding our TPU product range, GPP is another example of our commitment to replace legacy technologies with engineered belt solutions that are more efficient, lighter, cleaner, safer and quieter to operate than traditional roller chains, and last up to five times longer than steel cables.”

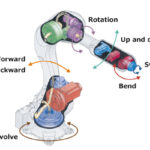

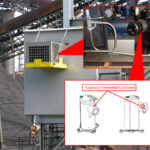

Engineered to outperform the competition, the high-strength, reinforced steel (RSL) GPP 14-RSL has the highest break strength of any 14-mm pitch TPU belt on the market, and the standard product versions are compatible with Timken’s RPP sprockets, making them suitable drop-in replacements across a wide range of applications. All Gates GPP belts are equipped with nylon fabric on the tooth sides for high abrasion resistance and quieter operation, and the optional low-temperature construction provides an operating range from minus 30° up to 50° C. GPP belts complement Gates’ existing TPU belt line-up and provide reliable, precision operation across a wide range of industrial applications, including intralogistics, material handling, vertical lift, door opening and industrial automation.

GPP belts are currently available in the North America and EMEA regions.

Gates

www.gates.com

You may also like:

Filed Under: Belts + chains