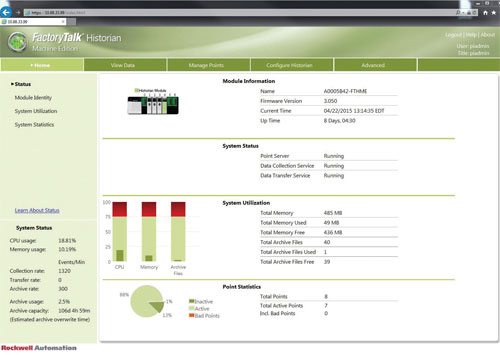

The FactoryTalk Historian Machine Edition (ME) v3.5 module enables off-chassis data collection from a modular historian. Operators using Allen-Bradley ControlLogix and CompactLogix controllers can collect data from controllers and devices connected through the Ethernet network.

A modular historian can be needed in operations that require data collection in remote or hazardous locations, and when speed and reliability is crucial, such as oil and gas, mining, pharmaceutical, or water treatment applications. With the v3.5 update, each FactoryTalk Historian ME module is more flexible and expandable with the ability to collect performance data by remotely connecting to controllers both on- and off-chassis. An intuitive auto-discover feature means the historian module recognizes controllers without additional or custom coding.

The FactoryTalk Historian ME v3.5 update also provides security. The module uses a self-signed SSL (secure socket layer) certificate out-of-box, for tighter security when viewing module data through the Web.

New add-on profile (AOP) functions help operators proactively monitor the health of their module through a dashboard or notifications. Detailed information can be obtained for any controller the FactoryTalk Historian ME module is connected to, and AOPs can be configured while the controller remains online.

FactoryTalk Historian ME v3.5 module allows a single module to collect up to 2,500 data points from five local and five remote controllers connected by Ethernet. Remote data collection with the module is ideal for applications requiring a collection speed of 500 msec or slower. Local data collection can reach speeds as fast as 10 msec. The new software is currently shipping with FactoryTalk Historian ME modules. Existing FactoryTalk Historian ME users can download the firmware update.

Rockwell Automation

rockwellautomation.com

Filed Under: Ethernet — cables • hubs • switches, MOTION CONTROL

Tell Us What You Think!