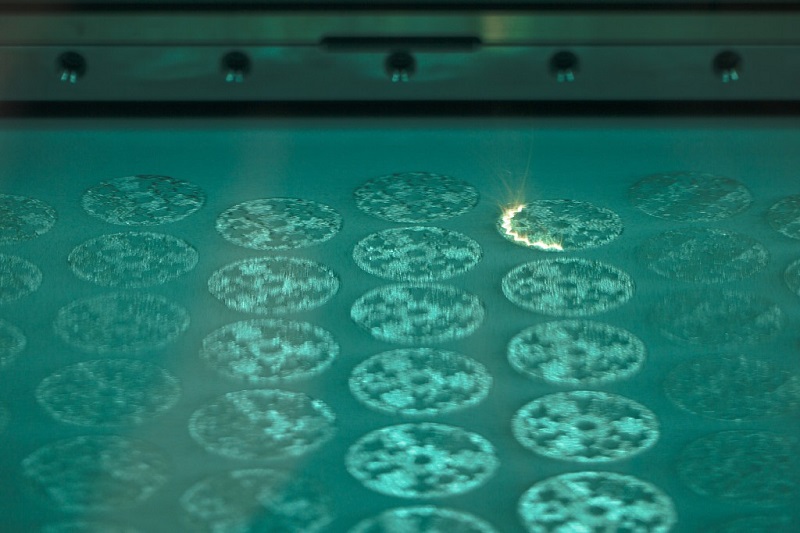

A DMLM laser printer in action at GE’s Center for Additive Manufacturing Advancement. Image credit: GE Reports/Chris New

3D printing companies Arcam AB and SLM Solutions Group will be folded into GE in a $1.4 billion deal, GE announced today. They’ll add a portfolio of products and capabilities, including airplane parts and medical scanners.

Arcam AB, based in Sweden, and SLM Solutions Group in Germany are top-tied additive manufacturing companies, GE said.

“Each bring two different, complementary additive technology modalities as individual anchors for a new GE additive equipment business to be plugged into GE’s resources and experience as leading practitioners of additive manufacturing,” said GE Aviation President and CEO David Joyce. “Over time, we plan to extend the line of additive manufacturing equipment and products.”

Specifically, SLM makes machines that use laser beams to fuse powder. Up to 1,250 layers of powder per inch go into the final product. Arcam makes parts using electron beams, which enable the company to manipulated tough materials such as titanium aluminide which may be hard to handle using traditional manufacturing processes.

At the moment, GE Aviation parts made using 3D printing are used on Airbus A320neo passenger jets operated by Pegasus Airlines in Turkey. GE provides up to 20 3D-printed nozzles for the LEAP engines used in the jets. GE Aviation is also working on a turboprop engine design for an upcoming Cessna aircraft, which is almost entirely 3D-printed.

GE’s Center for Additive Manufacturing Advancement in Pennsylvania was opened in April to hold a variety of additive manufacturing projects from around the different GE businesses, including GE Aviation.

Both acquisitions will be public tender offers for the companies’ outstanding shares of stock.

Filed Under: 3D printing • additive • stereolithography, Industrial automation