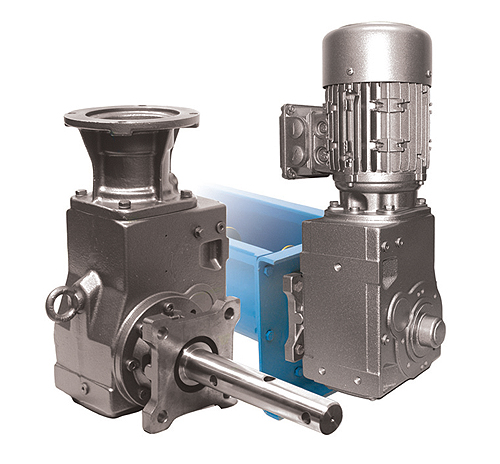

The newly designed right angle bevel products let you install gearboxes in confined spaces. The right angle bevel series is more compact compared to the existing parallel helical screw conveyor package. Its right-angle design is compatible with standard CEMA mounting. The three-hole tapered CEMA drive shaft is easy to mount and remove if needed. Its adjustable flange allows multiple bolt patterns. The sealing system includes dual Viton® lip seals, grease impregnated packing seal, dual gap seals, material evacuation ports, a shaft material ditch and QuadrilipTM sealing.

These gearboxes use either the direct-coupled gearmotor or NEMA C-face input design. This design eliminates the need for a separate V belt, which can add parts and lower drive performance.

These helical bevel screw conveyor drives produce torque levels ranging up to 42480 lb-in. and powers up to 30 hp, depending on the model. Each model operates on a 95% efficiency level or greater.

They also include the UNICASE™ design. Speed reducer housings are constructed of one solid cast-iron piece containing the bearings and seal seats, which eliminates the need for splits or bolt-on carriers that can weaken the housing and allow oil leaks. This cast-iron design can withstand weight from the heaviest loads.

The AUTOVENT™ breather regulates airflow and controls pressure inside the gear case. It also protects bearings by blocking out environmental materials like water, dust and corrosives.

NORD Gear Corporation

www.nord.com

Filed Under: Material handling • converting, MECHANICAL POWER TRANSMISSION, Gears • gearheads • speed reducers

Tell Us What You Think!