by Evan Yares, Senior Editor & Analyst, Software

It’s more about domain knowledge than software ease of use

A shift in CAE software started, quite a long time ago, when SolidWorks started including a basic version of Cosmos FEA with their eponymous CAD package. It was the beginning of the “red is bad, green is good” school of thinking, where ease of use started to become an increasingly important requirement for a new generation of CAE users.

That new generation has grown wildly. Consider, for example, the F1 in Schools challenge, in which teams of students aged 9 to 19 collaborate, design, analyze, manufacture, test, and then race miniature gas powered balsa wood F1 cars. Who would have thought that secondary school students would be using CFD code to design and analyze what are essentially toy cars?

Even though secondary students may be able to use CFD software to optimize the designs of model cars, the real F1 teams—the ones with big money riding on their results—know all too well that you can’t just give CAE programs to average design engineers (much less secondary students), and expect to get race winning results. These teams employ highly experienced CAE analysts, running large numbers of simulations, and spend massively on wind-tunnel and track testing to validate their results. Beyond this, many work with the top universities in the world, cooperating with and sponsoring academic research to improve the state of the art in CAE.

CAE companies can’t afford to ignore the market’s demand for ease of use. Yet, ease of use opens up CAE software to more misuse. It’s one thing to learn how to use CAE software; it’s a distinctly different thing to know what is required to get valid results with that software.

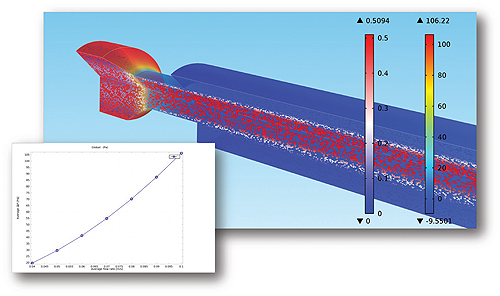

A flow and particle simulation of a nozzle for medical applications. The shear stress and fluid forces are computed, helping to assess the risk for blood damage, which frequently has to be accounted for when controlling the flow of medical devices. A good example of a real life problem, where domain expertise is critical.

Image courtesy COMSOL

Modeling challenges

The difficulty in getting good results with CAE comes down to more than creating a mesh, boundary conditions, and loads. It requires creating a model that captures a fundamental understanding of the problem.

Rick Nopper, a Senior Research Associate at DuPont Engineering, gave a presentation at the 2011 COMSOL conference, where he pointed out some of the challenges in modeling:

- Many real life problems are ill defined

- at the outset.

- Often, getting good input data is the most difficult task.

- Many problems are “multiphysics.”

- Many systems are disordered in some sense.

- Many problems are structured across multiple scale sizes.

- It is important to understand sensitivities to model parameters.

In short, many real life problems are challenging enough that they can only be solved by smart people with relevant domain expertise.

In the realm of CAE, there are increasingly more people who can run the software, but who don’t have the domain expertise to be able to prepare the analysis model so that it captures a fundamental understanding of the problem.

When designers are asked to do CAE, it’s natural for them to setup the simulation, press the “solve” button, and assume that the results are valid—that red is bad and green is good. It’s hard to fault them for making that assumption. With CAD software, bad results usually make themselves obvious through rebuild error messages. With CAE, bad results are often cloaked in pretty von Mises diagrams.

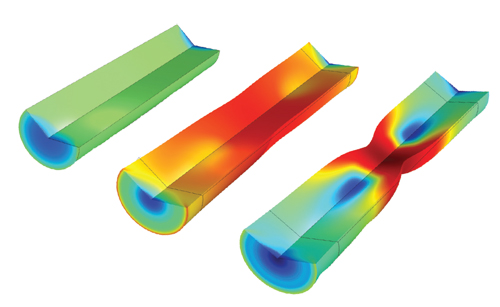

In this classic benchmark, a circular bar is subjected to a uniaxial tensile test, resulting in large deformations. All you need to know is that red is bad, and green is good. Real life problems are never this simple.

Image courtesy COMSOL

There’s no simplistic answer that guarantees valid simulation results. Certainly, a first step is education.

While many CAE software companies have training programs, one company that seems to do a particularly good job of this is COMSOL. Their two day multiphysics intensive training course spends most of its time on the practical and theoretical aspects of multiphysics modeling, and only a limited amount of time discussing how to use COMSOL software. This is how it should be: CAE education shouldn’t be about teaching people the quirks of a program. It should be about teaching people how to model real life problems. This course is suitable for anyone with an engineering, physics, or science background, and requires no previous experience with COMSOL Multiphysics.

Another good source of education is NAFEMS (originally the National Agency for Finite Element Methods and Standards, in the UK.) They offer courses throughout Europe and the United States, as well as through e-learning.

Beyond education, something that might be helpful, but seems not to be available, are tools to check simulation setups, to prevent or minimize CAE software misuse. While a number of vendors provide correlation and validation tools, to compare CAE results against measured test data, these tools don’t tell you the source of any error. They don’t look at look at your simulation setup; only at your results.

Though ease of use often contributes to CAE software misuse, it can be a positive thing as well. If you put a relatively easy to use CAE program into the hands of a person who has the domain knowledge to be able to accurately model a problem, they’ll be able to get more simulations done in less time. Of course, it’s also true that if you put that same program into the hands of a person who doesn’t have domain knowledge, they’ll also get more simulations done in less time. Those simulations just might not be all that reliable or useful.

F1 in Schools

www.f1inschools.com

COMSOL

www.comsol.com

NAFEMS

www.nafems.org

Filed Under: Software • FEA, Software • simulation, ENGINEERING SOFTWARE

I would say that domain knowledge is a given for any application. If you don’t know how to design a good valve for example, any software isn’t going to help you. If you don’t know how to use a hammer, don’t pick it up. All you will succeed in doing is hitting your thumb. High school students using CFD isn’t about them being domain experts. The reason such programs exist is to encourage them into STEM subjects at university so we can turn out the domain experts of the future.

The importance of ease of use is best understood by considering the number of individual settings that make up say a CFD model of a complex industrial problem. Thousands. Ease of use aims to automate as much as can be automated so that human error is minimized. Ease of use is a good thing, period, because of this. It is orthogonal to domain expertise. They are independent of one another, but both are needed to produce the consistently reliable results industry requires.

Hi Evan. Nice article. You are just scratching the surface of what it will take, strategically, to get the power of simulations reliably into the hands of many more engineers to produce “good enough” results for them, or others who rely on them, to make product engineering/design decisions. But you did scratch the surface and I hope it starts more discussion on this important topic. Are you aware of what I have started calling “The Walsh Curves” after Joe Walsh, who first drew them and used them in a similar presentation/discussion (at a CPDA/CIMdata workshop) about 16 months ago?