By Mark Pszczolkowski, Hydraulics Consultant at CD Industrial Group Inc., www.cdiginc.com

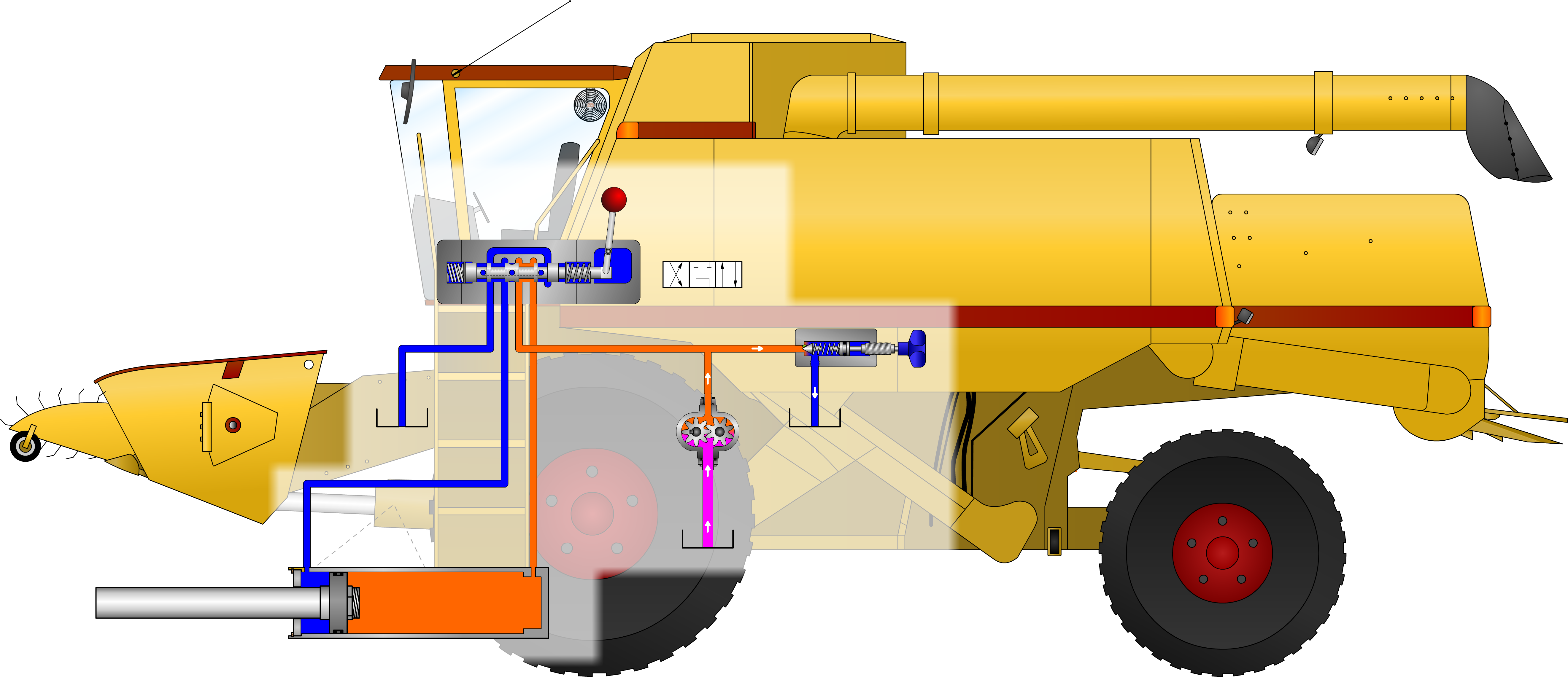

When the cylinder won’t lift the load, replace the pump! That’s a very common reaction to a hydraulic system failure. Last week this situation came around again as an almost annual harvest event. I was called by a farmer I know. His harvester has a cylinder to lift the header. The complaint was that the header would not lift up when the lift valve lever was pulled.

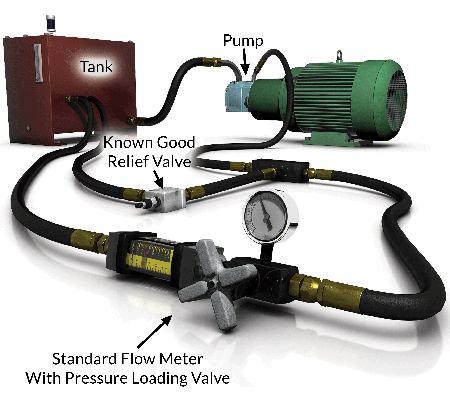

The farmer called the local dealership and a mechanic was dispatched to the farm. A number of tests were conducted without the use of any flow meters. The conclusion was that the pump had failed. The new pump would be $2,000.00.

That’s when he called me. My farmer friend asked if there was some way that I knew of to purchase the pump directly from a pump manufacturer—and save money over the dealer’s price.

I was more concerned with how the dealer mechanic had determined that the pump had failed when he had not used any flow meters. My farmer friend was convinced that the mechanic had done his job correctly. I then informed him that I didn’t have any inside track on a cheaper supplier. He went ahead and ordered the new pump.

He later called me again to report that after installing the new pump, the header lifting problem remained. The farmer was not pleased and wondered if perhaps he had done something wrong while installing the new pump. The dealer mechanic came out to the farm yet again and confirmed that the new pump had been installed correctly. The mechanic carried out further checks on the hydraulic system. While he had the relief valve disconnected he managed to release what he later referred to as “a chunk of material” that had been lodged in the main poppet. I wish he had saved that material for us to see, and learn about.

After reassembling the hydraulic system the lifting problem was resolved.This now made complete sense to me. The relief valve that was stuck open, was providing an easier path for fluid to flow back to the tank, as opposed to flowing into the heavily loaded cylinder.

Unless a pump has begun making a strange noise, or its case has turned black from extreme overheating, it is not often to blame for a sudden, total loss of flow. Always look through the circuit schematic to see where the flow from the pump might go, if not into the desired cylinder or motor. You are looking for another potential parallel path back to tank, such as that relief valve that was stuck open.

Unless a pump has begun making a strange noise, or its case has turned black from extreme overheating, it is not often to blame for a sudden, total loss of flow. Always look through the circuit schematic to see where the flow from the pump might go, if not into the desired cylinder or motor. You are looking for another potential parallel path back to tank, such as that relief valve that was stuck open.

It is also a valid strategy at some point, to test the pump and fully understand the capability of your fluid source. But in order to properly test a pump, a load test kit with flow meter must be used, and by a competent mechanic.

![]()

Filed Under: Hydraulic equipment + components