HAWE Hydraulics will be announcing a significant expansion to the range of products for applications of NBVP16 seated valves in booth F-2878 at the IMTS show, September 8-13, 2008 at the McCormick Place in Chicago, Illinois.

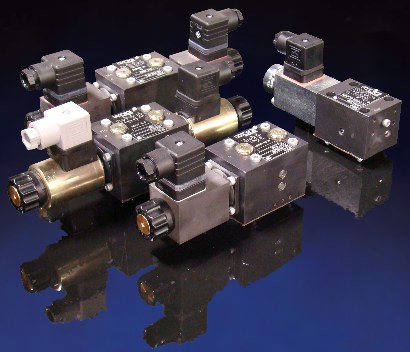

The NBVP 16 seated valves are designed for clamping functions in machine tools, machining centers, and energy efficient systems. HAWE has significantly expanded the range of possible applications by designing several new flow patterns for the cone seated valves of type NBVP 16.

While typical 2/2, 3/2, 4/2 and 4 way 3 position functions of directional valves can be fulfilled with either spool valves or seated valves, the seated valve offers significant advantages. Zero leak seated valves eliminate the need for pumps to continually charge a hydraulic system, as they would need to do when using spool valves. This valve is also more tolerant of contamination in the system due to its design and constant flushing.

The seated valve also offers energy-saving intermittent service, and reduces the required volume of oil. Once the clamping pressure has been reached, the valve ensures that the clamping pressure is safely maintained. The pump itself switches off or goes into circulation mode until the next clamping sequence, while the power units cool the system down through its design characteristics.

HAWE‚’s modular design system provides different types of 2/2, 3/2, 4/2 and 4/3 seated valves with NG6 or D03 standardized connection diagram. The maximum operation pressure is 5800 psi and the maximum flow 5.28 gpm. The available actuators are solenoid, hydraulic, pneumatic or manual, as well as an ATEX solenoid version for hazardous environments.

www.hawehydraulics.com

::Design World::

Filed Under: Valves, FLUID POWER

Tell Us What You Think!