At MD&M WEST 2017, Herrmann Ultrasonics introduces two features to ensure more safety when changing welding tools within the production process.

Firstly an RFID reader has been integrated into the tooling which guarantees that the right tool is installed for the production. Not only is it built into the sonotrode but also into the fixture. The ultrasonic welding system automatically associates the correct parameter setting for parts to be welded with the installed tooling. Medical device manufacturers will benefit from this new feature as it adds immense production security.

Adding a second level of security is the integration of an optical sensor. Before each ultrasonic welding process, it verifies that the correct part in terms of shape and colour has been placed into the fixture. If the system recognizes a mismatch, it locks the process, alarms the operator or puts the system on hold.

Both features can be easily integrated into the successful HiQ series ultrasonic welding machines, the HiQ DIALOG and the HiQ VARIO (see image 01), without having to add any additional external hardware or software. All elements are already available within the software solution package.

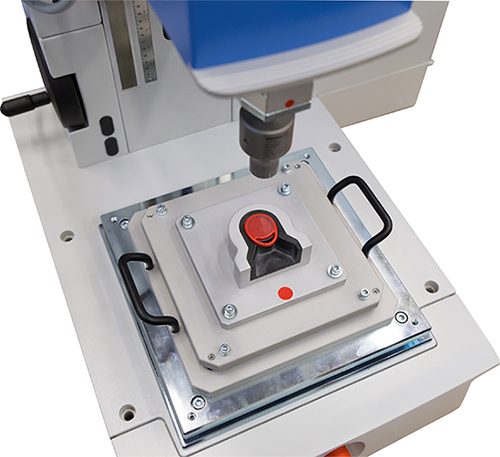

During MD&M WEST 2017, Herrmann Ultrasonics will demonstrate a HiQ VARIO with RFID reader (see image 02) in its booth # 3101. Stop by for test welds and get more details about the unique ultrasonic welding technology in combination with RFID!

During MD&M WEST 2017, Herrmann Ultrasonics will demonstrate a HiQ VARIO with RFID reader (see image 02) in its booth # 3101. Stop by for test welds and get more details about the unique ultrasonic welding technology in combination with RFID!

Good to know: RFID stands for Radio Frequency Identification and it usually refers to small electronic devices that consist of a small chip and an antenna. RFID devices have the same purpose as a bar code for unique identification. Similar to a bar code which has to be scanned for more details, the RFID device must be scanned to retrieve identifying information.

Hermann Ultrasonics

www.herrrmannultrasonics.com

Filed Under: Medical-device manufacture, MOTION CONTROL, SENSORS

Tell Us What You Think!