H2W engineers have developed a compact high force brushless linear motor (BLSM-1F) that can generate 300 lb (1330 N) at a 10% duty cycle and 100 lb (444 N) at a 100% duty cycle, and, when used with a matching magnet track (BLST-FSX). The mass of the coil assembly is 19 lb (9 kg) which gives a force to moving mass ratio of 15:8.

The motor can be driven using either a trapezoidal or digital standard three phase brushless amplifier. The brushless linear motor coil measures 6.53 x 7.50 x 1.50 in. (170 x 190 x 38 mm). This brushless linear motor is designed for applications that need a wide speed range and a relatively high force. This motor is encapsulated using high temperature 350° F (176° C) thermally conductive potting compound … which protects the components and seals it from dust and moisture.

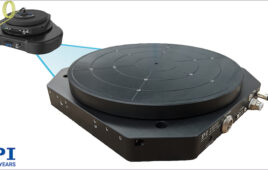

The three-phase brushless linear motors, also known as an ac linear servo motors, are direct drive motors that are suitable for long stroke, closed loop servo, linear motion applications. They can be used at speeds up to 240 in/sec (6 m/sec). They are capable of very precise position, velocity and acceleration control when coupled with a linear encoder for position feedback.

The laminated three-phase wound coil assembly is used in conjunction with a linear magnet track to produce a controlled linear force. A customer supplied bearing system is needed to maintain the 0.060-in. (1.5-mm) air gap between the coil assembly and the magnet track. There’s a relatively large attractive force between the motor coil and the magnet assembly. The magnet track consists of rare earth neodymium magnets and the need overall length is equal to the coil assembly length plus the stroke length.

Iron-core brushless linear motor advantages:

• Uses a standard three-phase brushless amplifier; multiple coils can operate on the same magnet track assembly

• Unlimited stroke length; high force to moving mass ratio

• Magnetic attractive force between the coil and magnet track assemblies creates preload for a bearing system

Typical brushless linear motor applications include conveying systems, baggage handling, coordinate measurement machines, laser and water jet cutting, and pick-and-place machinery.

H2W Technologies, Inc. is dedicated to the design and manufacture of linear and rotary motion products that are used in the motion control industry. The complete line of linear electric motors includes: Single and dual axis linear steppers, DC brush and brushless linear motors, voice coil actuators, and ac induction motors. Also offered is a complete line of ball screw, lead screw and belt driven positioning stages. Other motion control products include limited-angle torque motors as well as three-phase brushless rotary servo motors (with matching digital servo amplifiers and permanent magnet linear brakes) for fail-safe, zero power braking … for baggage handling, people moving, and amusement-park rides. For more information, email [email protected] or or visit h2wtech.com.

Filed Under: Encoders • linear, Linear Motion Tips, Motors (direct-drive) + frameless motors

Tell Us What You Think!