Del-Tron’s belt-driven DB series actuators operate at speeds to 5.1 meters per second (MPS) and does not require lubrication or maintenance under normal operating conditions. They are ideal for use when speed is critical, such as pick-and place applications on high speed automation equipment. They can also provide travel lengths to six meters while maintaining repeatability of +/- 0.025 mm and linear accuracy of +/- 0.083 mm per meter.

Positive Belt Drive

New DB series actuators have a steel-reinforced polyurethane belt that helps deliver repeatable positioning by avoiding belt stretching. The positive timing belt drive makes further improvements in accuracy and speed. A proprietary extrusion design provides long travel, smooth movements, and excellent repeatability. DB series actuators are available standard to accept NEMA 23, and 34 motors and can be configured to accept other sizes

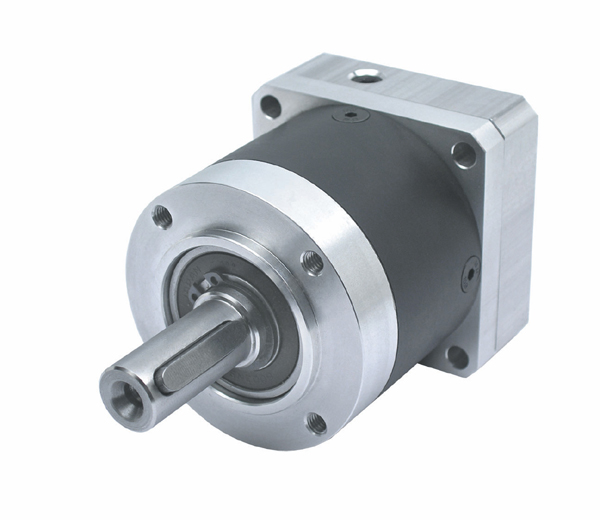

High Output Gearheads

The DB series planetary gearheads contribute to the performance of the actuators by providing gear geometry optimized for planetary systems using zero helix angle gears to avoid unbalanced forces caused by helical gears. Generously-sized sealed deep-groove ball bearings support the output shaft. All gears are case hardened for high surface hardness and high strength ductile core. The gearhead handles input speeds to 10,000 rpm and delivers exceptionally high output loads.

Steel or Plastic Bearings

Three different types of bearings are offered. Steel concave rollers (DBM) riding on chrome-plated steel rails give excellent positioning accuracy even in applications that require long travel. A plastic coated needle (DBN) bearing assembly offers the highest possible speeds. Plastic bearings (DBP) running on aluminum rails provide the ultimate in durability in tough push-pull applications. The steel bearings are supplied with lifetime lubrication while both types of plastic bearings require no lubrication at all.

Custom Designs

Del-Tron applications engineers can help you select the appropriate belt actuator and gear box for your application. Del-Ton can also provide special designs of DB series actuators for nearly any application.

Del-Tron Precision, Inc

www.deltron.com

Filed Under: Factory automation, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!