A combination of software application and technical expertise resulted in the development of a specialized device to help patients with neuromuscular disabilities regain mobility. The Cleveland FES Center used MathWorks’ Model-Based-Design software to build custom functional electrical stimulation (FES) prototypes. FES devices restore movement to paralyzed arms and legs. They send electrical impulses to electrodes—implanted in the body, worn on the skin, or operating through the skin—to produce and control movement. Adapting the FES device for each patient was a time-consuming process because the device software needed multiple iterations for a custom response to each patient’s needs.

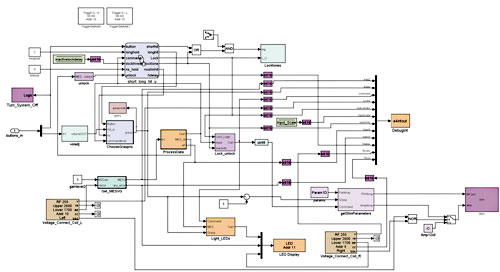

Application developed by a clinician to provide arm and hand control using an implanted stimulator.

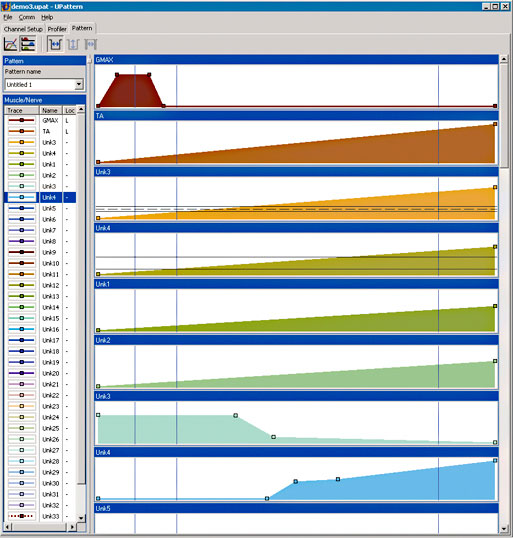

The Cleveland FES Center, at Case Western Reserve University, developed the Universal External Control Unit (UECU) to address the need for tailored FES devices. With the UECU’s modular software and hardware design, research engineers in the clinic can modify a FES controller application and immediately test the results. With MathWorks tools, teams are able to develop, test, and implement algorithms that suit specific patient scenarios, reducing the traditional development cycle for some FES functions to less than a day.

The pattern editor enables clinicians to rapidly create new stimulus patterns and fine-tune FES applications.

“All of our FES applications used to be built by dedicated programmers using C code,” said Robert Kirsch, PhD, Professor, Biomedical Engineering, Case Western Reserve University and Associate Director of Technology, Cleveland FES Center. “The overall process was slow because everything had to be done by our central programmers, which limited how quickly we could move from idea to implementation. MathWorks tools for Model-Based Design provide the flexibility and ease of use that enables our clinical groups to develop and refine FES applications on their own.”

The MathWorks

www.mathworks.com

Cleveland FES Center

www.FEScenter.org

Filed Under: ENGINEERING SOFTWARE, Medical-device manufacture

Tell Us What You Think!