As governments around the world pass stronger emission standards, the demand for electric vehicles continues to grow. This trend, in turn, will lead to the rapid increase in the use of large gauge wire and cables. Based on predictions from Morgan Stanley in 2017, four out of five cars sold worldwide will be battery-electric vehicles by 2050. Therefore, proper termination of high voltage connectors requires a high-performing, highly engineered solution. TE Connectivity (TE) has developed a high force termination solution product line that provides customers the power needed to terminate high voltage connectors in a fast, flexible and compact benchtop format.

TE Connectivity’s HV 20 high-voltage wire crimping solution

The HF-20T and HV-20T terminators, along with an advanced high-force modular die platform, represent a new era in high voltage wire crimping and further strengthen TE’s position as a supplier to automotive wire harness makers worldwide.

The new terminators’ attractive differentials and features include:

- Ability to process wires up to 120 mm2 – Unlike competitive offerings, TE terminators can produce 178 kN or 20 tons of crimp force, while delivering variable speed control.

- Greater manufacturing flexibility – A modular die platform allows customers to use an array of unique die sets in holders that can be installed into either machine — the HF-20T or the HV-20T. A fine adjust feature allows for faster, more precise crimp height adjustment.

- Industry 4.0 ready – The new line of high force terminators provides sophisticated controls, a traceability system, as well as Ethernet and USB ports.

- Integrated vacuum system – The system on the HV-20T model keeps sensitive connections clean and clear of debris commonly associated with high voltage cable crimping.

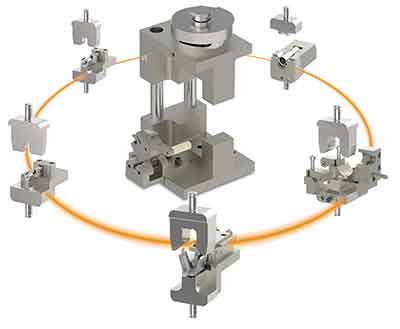

TE Connectivity’s high-voltage modular die system

“Given the ever-growing demand for hybrid electric vehicles, our automotive customers need a solution for the mass production of wire harnesses,” said Eric Broadaway, director of product management and pricing for the Application Tooling division of TE. “With the introduction of our high voltage portfolio, wire harness manufacturers are now able to increase their throughput four to eight times faster than they could with our prior offering.”

“Our new high force product line represents the culmination of more than a year of development. In addition to acknowledging the outstanding performance of our team, I also want to thank our global customers who provided a guiding voice throughout the entire evolution process. With such collaboration, we are confident this product offers differentiated value to our customers in this exciting and ever-growing market,” added Beth Schroeder, general manager of Application Tooling.

TE’s high voltage wire processing lineup will only continue to expand and new additions and innovations will be coming soon. A high voltage terminator will be on display at the upcoming productronica tradeshow in Munich, Germany, from Nov. 12-15 (Hall A5, Booth 321).

TE Connectivity Ltd.

www.te.com

Filed Under: Connectors (electrical) • crimp technologies

Tell Us What You Think!