Coil springs and wave springs are both types of compression springs, meaning the spring’s force increases as its axial length decreases (as the spring is compressed). But coil springs and wave springs react differently to applied loads, especially in terms of how stresses are created in the material, which in turn, affects their working load and the linearity of their load-deflection characteristics.

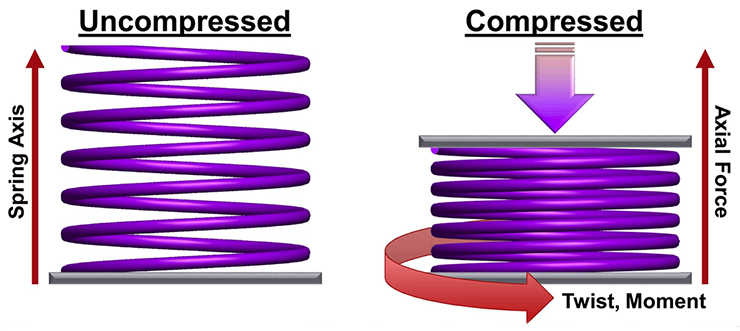

When a load is applied to a coil spring, the spring experiences both axial and torsional forces, which create axial and torsional shear stresses. This torsional loading can cause the spring to twist, resulting in unintended forces and misalignment of the mating parts. In addition, as the spring attempts to twist, friction between the ends of the spring and the mating parts can cause the spring force to be erratic and deviate from the spring’s load-deflection curve.

Image credit: Shigley’s Mechanical Engineering Design

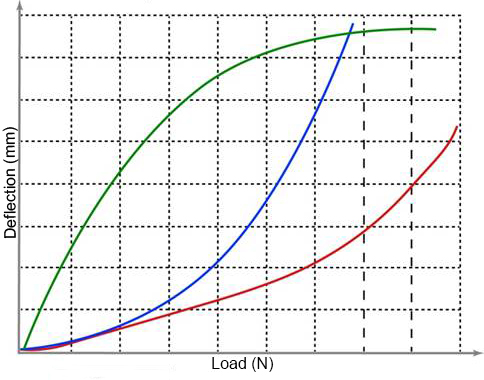

The combination of axial and torsional shear stresses also reduces the spring’s working load. And coil springs have relatively small linear force regions — the area of the load-deflection curve where force varies linearly with deflection. This makes it more difficult — and less reliable — to predict the spring’s force for a given deflection, which can be detrimental in applications such as mechanical seals, where the relationship between deflection and force is critical for proper operation.

Image credit: Rotorclip

Image credit: Smalley

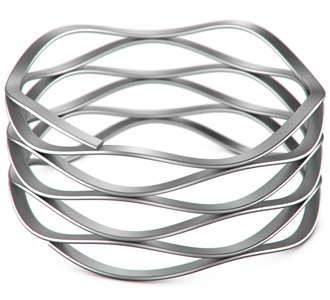

Wave springs are differentiated from coil springs primarily by their rectangular cross-section. Instead of being made from round wire, wave springs are made from flat wire with waves added to each turn of the spring. This designs means that wave springs flex, similar to a beam, when under load. Rather than twisting as a load is applied, the waves on a wave spring “flatten” and provide an upward force, so all the load on the spring occurs in an axial direction.

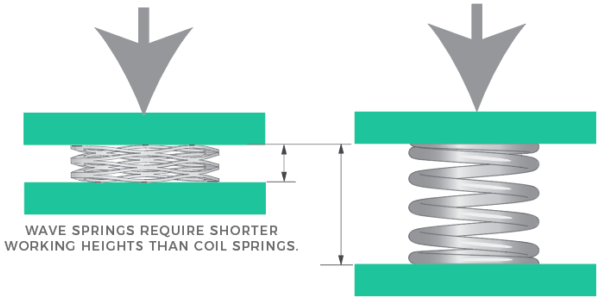

And because the flat wire has a smaller cross-section than round wire, wave springs can have significantly smaller free height (height when not loaded) than a coil spring with a similar spring rate.

Image credit: Lee Spring

Although wave springs aren’t always a suitable replacement for coil springs — in applications that require a long travel or very high loads, for example — they are ideal for installations that require precise force at a given deflection and for those with limited radial or axial space.

Filed Under: Motion Control Tips